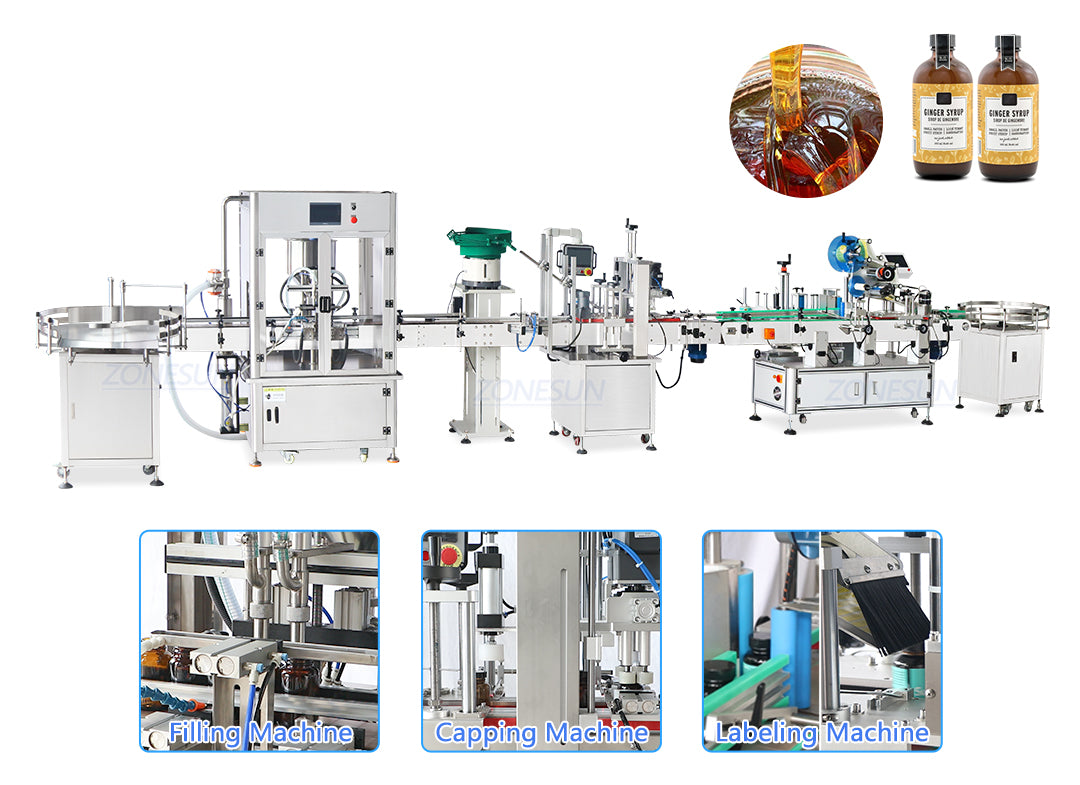

Mesin Madu Isi Capping Labeling

Campuran & fungsi pemanasan bisa disesuaikan

Kepala ngisi macem-macem bisa disesuaikan

Tampeling bukti sing paling gedhe

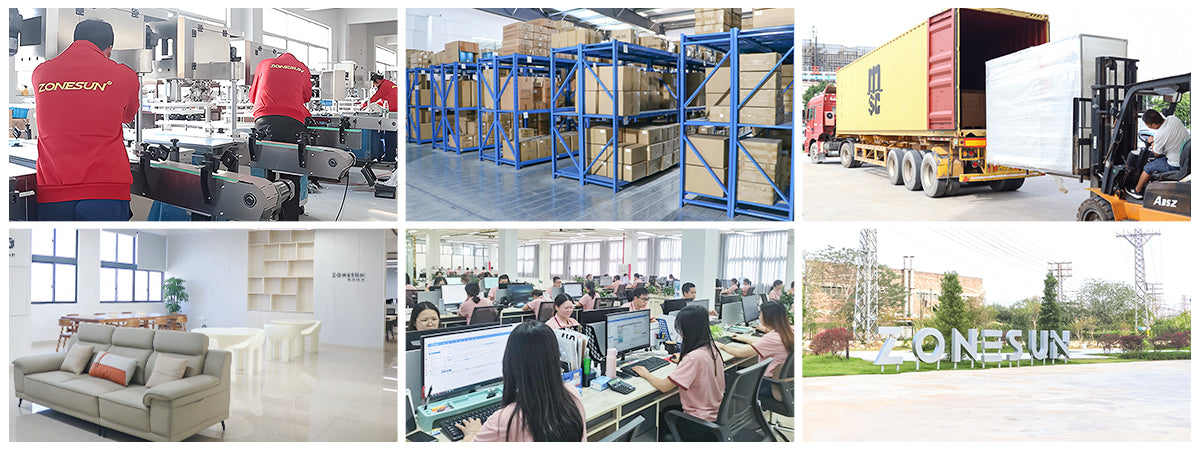

Nawakake solusi kemasan siji-mandeg

Nawakake dhukungan & dhukungan video lokal

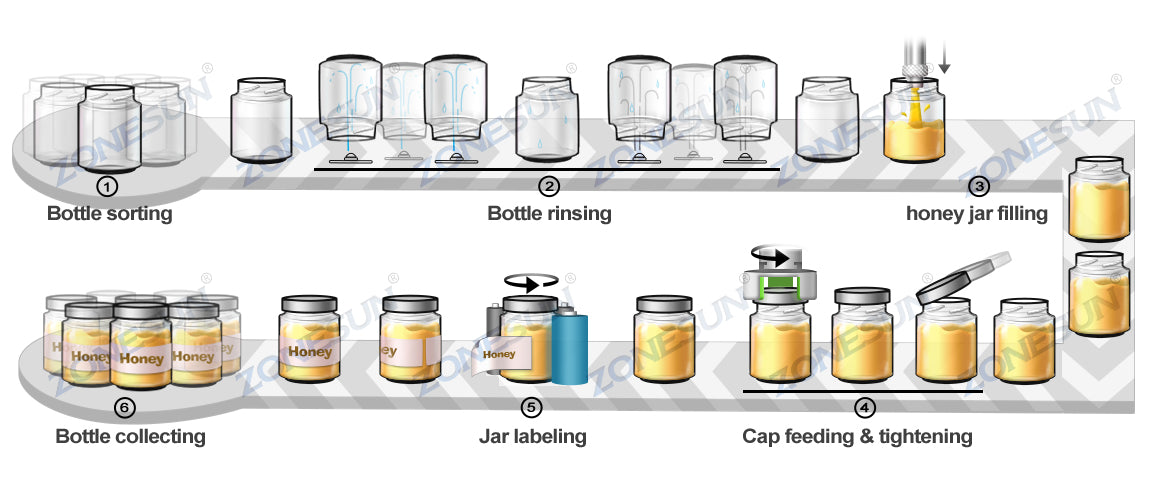

Honey Filling Packaging Process

Honey can be divided into liquid honey and creamed honey, which are two different forms based on their texture and processing: 1. Liquid Honey : This is the most common form of honey, which is in a liquid state at room temperature. It is extracted from the honeycomb and then strained to remove any wax particles. 2. Creamed Honey: Also known as whipped honey, spun honey, or churned honey, this form of honey has a smooth, spreadable consistency. Creamed honey is produced by controlling the crystallization process. Small seed crystals are added to liquid honey and then the mixture is stored at a cool temperature, which encourages uniform crystallization. The result is a honey that is thick and creamy, making it easy to spread on bread and other foods. Both types retain the natural flavors and beneficial properties of honey. The viscosity of honey can vary depending on its composition, temperature, and water content. Generally, honey is quite viscous, meaning it flows slowly. At room temperature (around 20°C or 68°F), the viscosity of honey typically ranges from 2,000 to 10,000 centipoise (cP). However, this value can decrease significantly if the honey is heated, making it flow more easily.

Tantangan kanggo ngisi madu

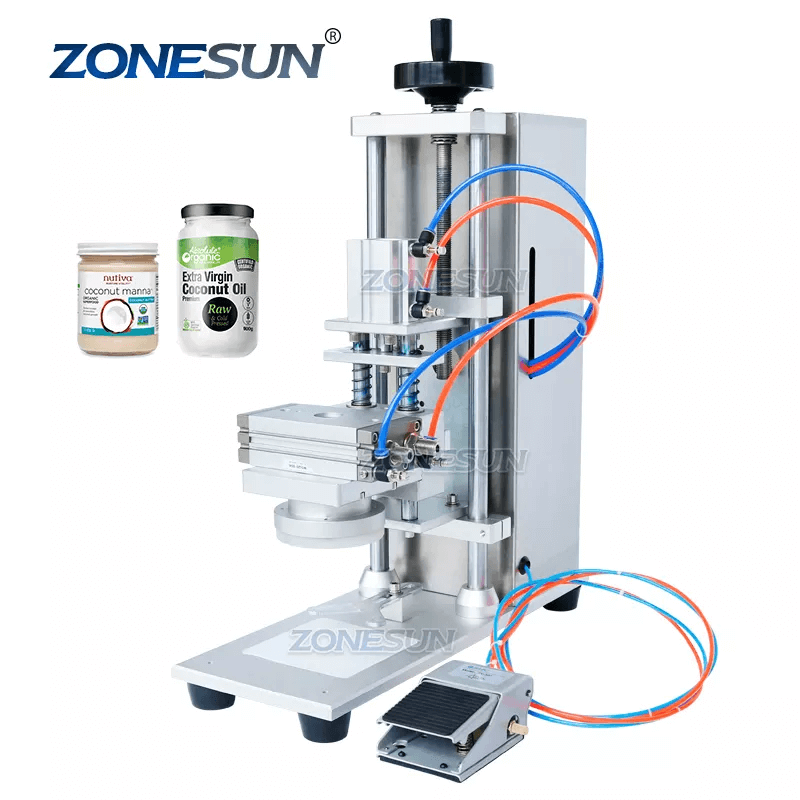

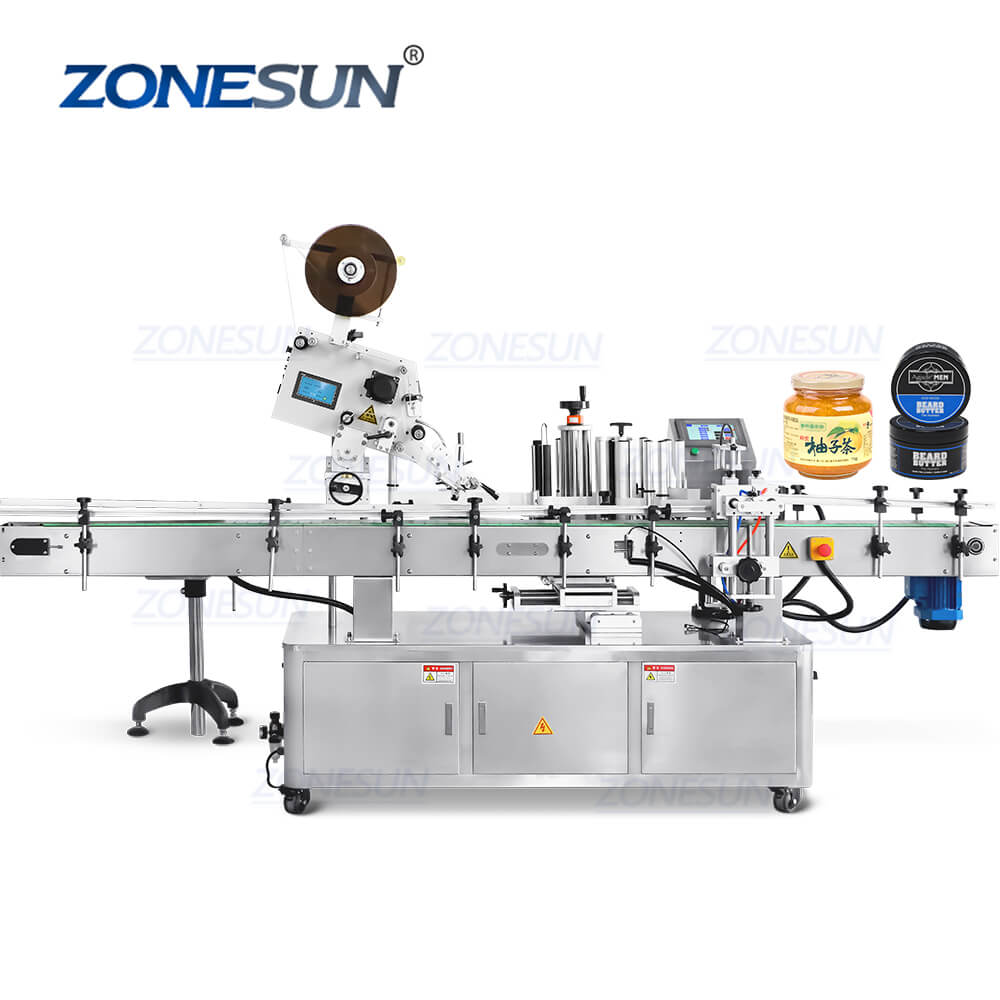

Isi kanthi macem-macem ukuran kontaner

Kanggo sawetara produsen madu skala ukuran cilik utawa medhia, mula kudu gampang ngganti macem-macem ukuran kontaner kanthi macem-macem ukuran caps.We bisa menehi produksi kanthi gampang kanggo nggunakake mesin.

Fungsi Pemanas & Nyampur

Yen aditif kayata rempah-rempah, rempah-rempah, utawa bahan liyane kalebu njaga kualitas madu sing konsisten kanggo nggunakake viskositas madu, luwih gampang ditangani nalika ngisi proses.

Isi anti-netes

Madu Cairan lan madu sing creamed asring nuduhake ketegangan permukaan sing dhuwur, lan kekirangan sing dhuwur bisa nyebabake madu kanggo ngepelake tembok utawa nggawe gandum sing diisi saka botol utawa madu bakal cling Lumahing njaba nozzle, sing ndadungake netes. Kanggo ngrampungake masalah iki, kita nawakake muncung Isi anti-nething, iki bisa nyegah madu sing netes kanthi efisien.

Bahan mesin lan papan kerja

Peralatan kanggo produksi madu biasane dibutuhake kanggo tahan suhu sing dhuwur, lan materi kasebut kudu disesuaikan karo baja stainless steel kelas kanggo njamin keamanan sajrone proses produksi. Uga, sawetara produsen madu ukuran cilik lan medhia bisa uga ora cukup kerja. Zonesun bisa nyedhiyani mesin kemasan sing cocog karo syarat produksi miturut kabutuhan pelanggan.