This automatic bottle capping machine has two working structure, one for pressing bottle stoppers, another one is for capping outer covers.It is equipped with vibratory bowl sorter to make stoppers and outer covers be in order before packaging work.This machine is designed for the daily chemical industry.

Parameter

- Machine model:ZS-XG16X

- Voltage:110/220V 50-60hz

- Working voltage:220V/110V 50- 60HZ

- Bottle height:30-300mm

- Cap diameter:18-70mm

- Bottle diameter:20-160mm

- Working speed:10-25 bottles/min(depending on cap size and shape)

- Working pressure:0.4-0.6MPa

- Size of air compressor connector:OD 8mm

- Package size:About 1970*510*990mm(Stopper Pressing Machine)+2020*770*1750mm(Screw Capper)

- Gross weight:About 104kg(Stopper Pressing Machine)+303kg(Screw Capper)

The PLC control panel can shows working data in real time, more intuitive interface can simplifies machine operation. It can be customized into different kinds of language according to production need.

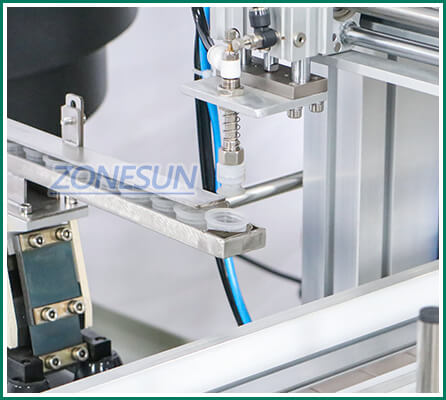

Controlled by air cylinder, the air nozzles can pass stoppers and put them onto bottle mouth like human hand, this suits the light caps or stoppers, it has high working accuracy.

By automating the sorting process, vibratory bowl sorting machines reduce the need for manual labor, resulting in increased efficiency and productivity. They are customized according to stoppers and caps size, and have high working accuracy.

Working height and position of capping structure can be adjusted according to bottle cap size and shape.This kind of capping structure is suitable for various kinds of caps like spary caps, dropper bottles, sharp pointed bottles.

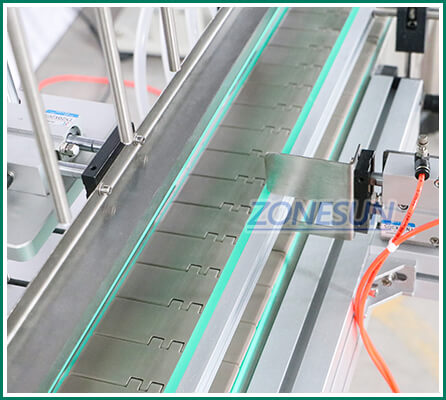

Length and width of chain conveyor can be customized according to production needs. It has larger weight capacity and can convey products more stably and smoothly.