The carton packaging machine is a piece of industrial equipment used in manufacturing and packaging processes to automate the formation, filling, and sealing of cartons or boxes. These machines are commonly used in various industries, including food and beverage, pharmaceuticals, cosmetics, and consumer goods, to streamline the packaging process and increase efficiency. Carton packaging machines come in different types and can include carton forming machine, carton sealing machine, carton folding machine etc.

Popular Categories

Does the carton packaging machine support different carton sizes?

Yes, most machines can be adjusted to accommodate various carton sizes. For frequent size changes, models with automatic size adjustment are recommended.

What is the difference between a Carton Erector, Carton Sealer, and Cartoning Machine?

Carton Erector: Automatically forms and erects flat cartons into a box shape.

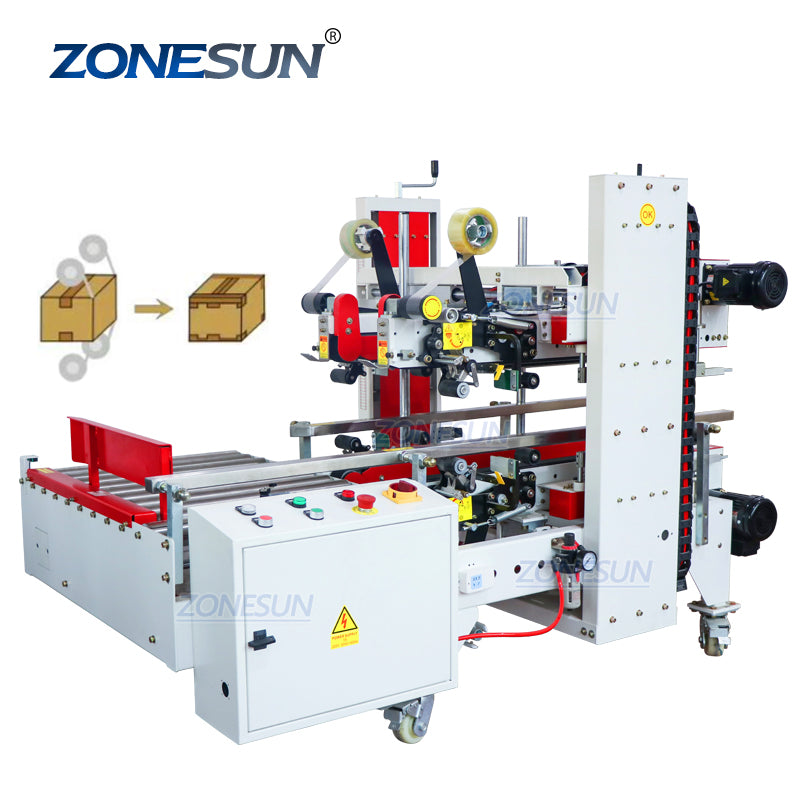

Carton Sealer: Seals the top and bottom of the carton.

Cartoning Machine: Loads products into cartons and completes the sealing process.

What is the working speed of the machine?

The speed depends on the specific model and function:

Carton Erector: Forms 600-900 per hour.

Carton Sealer: Seals 600-900 per hour.

Cartoning Machine: Packs 10–50 cartons per minute.

High-speed models are available for larger production needs.

Can the carton packaging machine be customized for specific carton sizes or functions?

Yes, the machine can be customized to meet your specific requirements, such as special carton sizes or additional features like hot melt glue sealing, labelers, or printers.

What are the requirements for cartons when using the machine?

- Cartons should be sturdy and suitable for automatic forming and sealing.

- Pre-folded creases should be clear for smooth unfolding.

- Carton dimensions must fall within the machine’s supported range.

What are the common issues with carton packaging machines?

- Issue 1: Cartons fail to unfold smoothly.

Cause: Carton material is too rigid or creases are unclear.

Solution: Use suitable carton material or adjust the gripping force of the machine. - Issue 2: Carton sealing is not secure.

Cause: Misalignment of tape or hot melt glue.

Solution: Check tape installation and adjust the sealing head position. - Issue 3: Machine runs sluggishly or stops.

Cause: Sensor malfunction or transmission blockages.

Solution: Clean the sensors and remove any obstructions.

Is this carton packaging machine suitable for my production line?

Carton packaging machines can operate independently or be integrated into fully automated packaging lines. Compatibility depends on your production requirements, such as output, carton types, and the configuration of other auxiliary equipment.