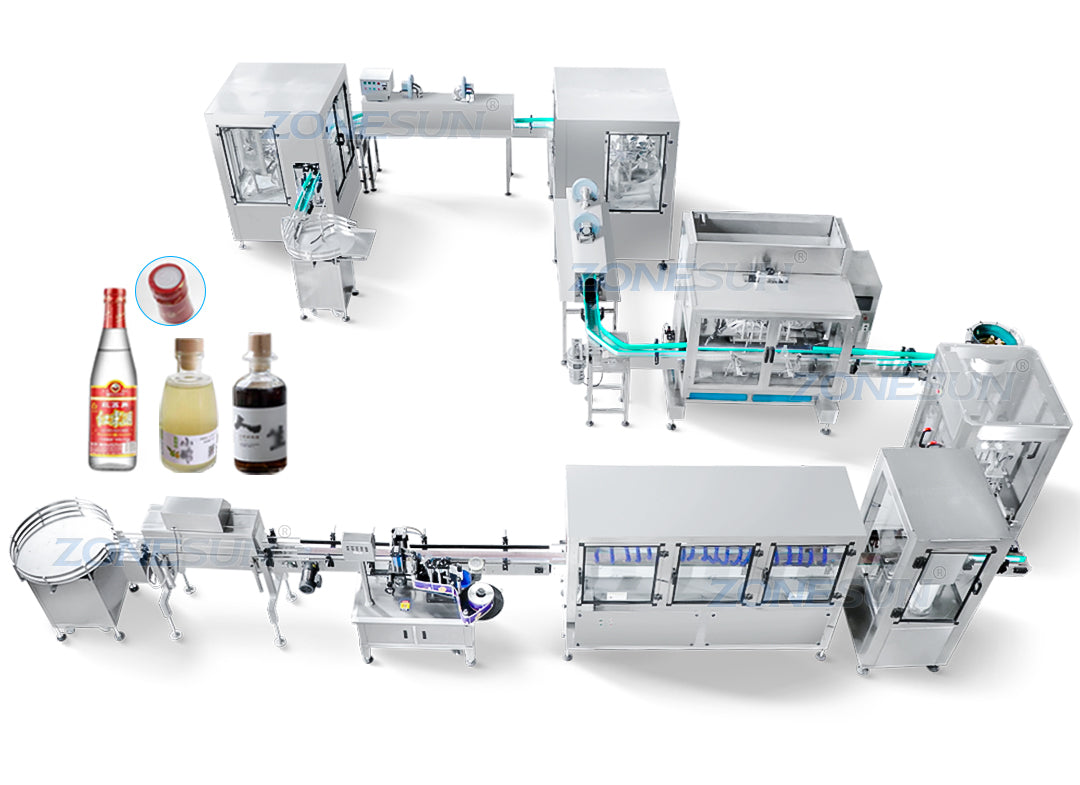

Liquor Bottle Filling Line

Multi filling heads can be customized as needed

Bottle turntable machine, shrink band shrinkg machine, can be equipped with as production need

Offer one-stop packaging solution

Offer local service & video chat support

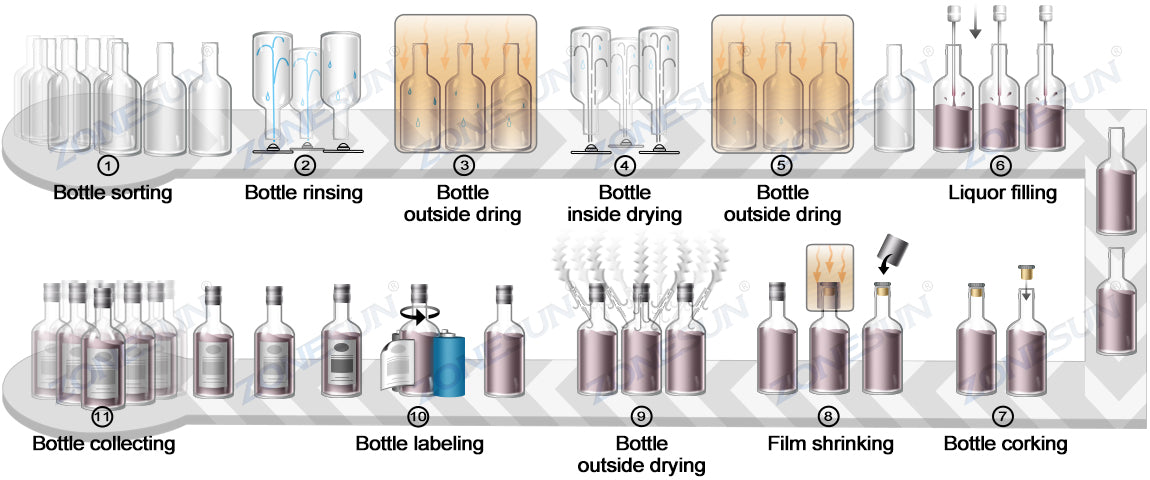

Liquor Filling Packaging Process

Liquor, also known as spirits, refers to alcoholic beverages that are produced by distilling fermented grains, fruits, or vegetables. Some common examples of liquors include whiskey, vodka, rum, gin, tequila, and brandy. They are often packed by glass bottles with t-cork or ropp caps(This is primarily based on factors such as product positioning, tradition, and cost considerations.) In general, liquors with higher alcohol content tend to have lower viscosity, meaning they flow more easily.

Challenge In Filling Liquor

Uneven filling

Liquors with high alcohol content tend to foam and splash more readily during the filling process. This can lead to inconsistent fill levels, product loss, and potential contamination if the foam comes into contact with equipment surfaces.In addition, since the quality and thickness of glass bottles are difficult to maintain consistent, this may also lead to the fact that even if the same volume of liquor is filled, the liquid level will not be consistent.ZONESUN has the liquid level filling machine to help you solve this problem

Handling Flammable Liquids

The high alcohol content of liquors poses a fire and explosion risk during the filling process, requiring strict safety measures, proper ventilation, and specialized equipment designed for handling flammable liquids.ZONESUN can offer ATEX filling capping machine to solve this problem.

Related Video For Liquor Packaging

Gin filling machine

- ZS-FAL180AD liquor filling line

- ZS-CB190 bottle accumulation table

- ZS-SXRS1 shrink band heating shrinking machine

- ZS-TB260 round bottle labeler

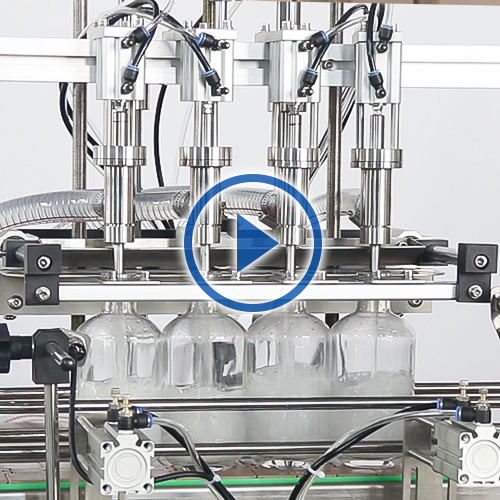

Tableto liquor filling line

- ZS-DTHSP2 tabletop filling machine

- ZS-XG1870D1 bottle corking machine

- ZS-TB500 bottle labeler machine

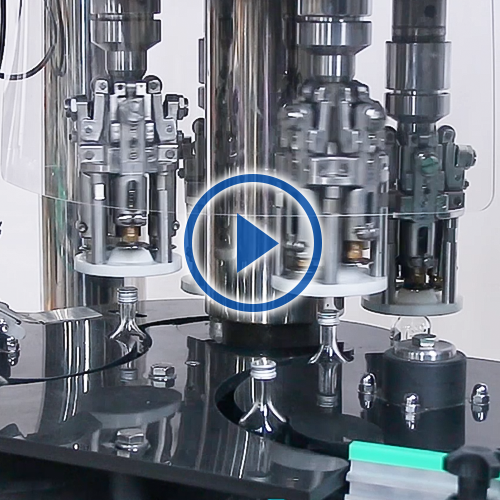

Whisky filling line

- ZS-YT4T-4PXD servo motor filling machine

- ZS-XG440Z inline ropp capping machine

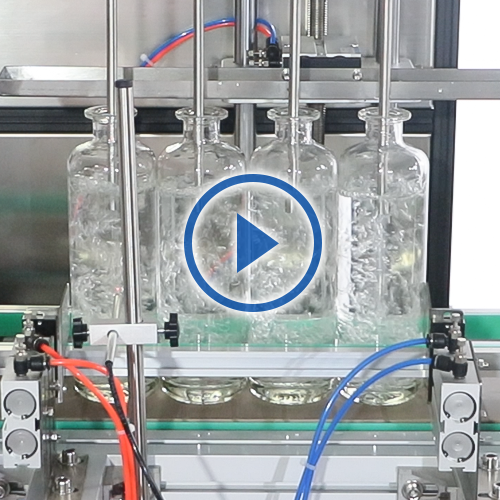

Inline liquor filling line

- ZS-VTMP80C magnetic pump filling machine

- ZS-XG16D3 bottle corker machine

- ZS-SXRS1 shrink band heating shrinking machine

- ZS-TB260R bottle label applicator