You may also like

Order now! Get at least 2% off here. Don't miss out!

- Home

-

Products

-

Industry

- Oversea Warehouse

- New Arrival

- Promotion

-

Your cart is currently empty.

Earn 0 points on this purchase.

The ZS-XG440C Automatic Pilfer-Proof Capping Machine is a high-performance solution designed to securely seal wine bottles, plastic bottles, and glass bottles with φ20-32 mm pilfer-proof caps. Engineered for efficiency and reliability, this machine ensures a tight, leak-proof seal, preventing tampering while maintaining product integrity.

With its fully automated operation, the ZS-XG440C significantly enhances production speed and consistency, making it an ideal choice for beverage, wine, cosmetics, and daily chemical manufacturers. Its advanced torque control system guarantees precise cap application, reducing waste and ensuring a professional finish on every bottle.

Built for seamless integration into existing production lines, this capping machine is a must-have for businesses looking to boost efficiency, enhance product security, and maintain high-quality packaging standards. Elevate your production process with the ZS-XG440C – the perfect blend of precision, speed, and reliability.

Simple control panel,it is easier to operate the machine.And the machine is designed with an emergency stop button,which can ensure the safety operation

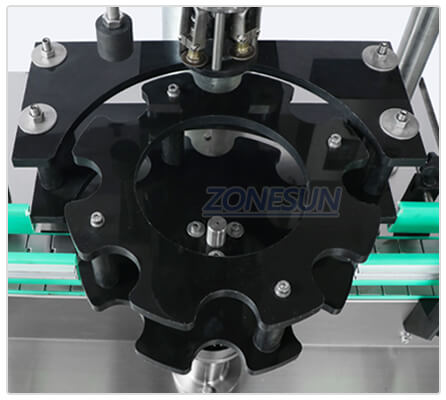

Round bottle separating plate is designed to arrange bottle in order.The size of this plate will be customized according to your bottle size.

To improve capping accuracy, the machine features a pressing head that secures bottle caps in place before tightening, resulting in a more consistent and professional seal. Additionally, we offer customizable multi-head capping options to match your production capacity needs, making it adaptable for both small-scale and high-speed production lines.

Equipped with stainless steel conveyor belt,it has large weight capacity,which can transfer bottles smoothly.It is available to customize longer conveyor belt according to production need.

The vibratory bowl capsorter is customized according to bottle caps diameter.It will help to arrange bottle caps before capping work,makes the production be in order and reduce production error.