This automatic bottle capper work with the cap elevator to realize automated cap feeding, and cap screwing.It is suitable for twist off bottles/jars, screw-on drinks bottle etc.It is usually work with automatic filling machine and labeling machine to realize automated production in jam, drinks industries.

Parameter

- Machine model:ZS-XG05

- Voltage:110/220V 50-60HZ 3KW

- Working speed:20-40 bottles/min(based on product size)

- Bottle height:About 80-300mm

- Bottle caps diameter:About Φ30-90mm

- Bottle caps height:Customized

- Air pressure:0.4-0.6MPa

- Machine size(L*W*H):About 3500-2000*2300mm(L*W*H)

- Machine weight:About 450kg

- Package size:About 2100*770*1770mm (Main Machine)+About 2200*870*1430mm (Cap Elevator)

- Package weight:About 286kg (Main Machine)+About 245kg (Cap Elevator)

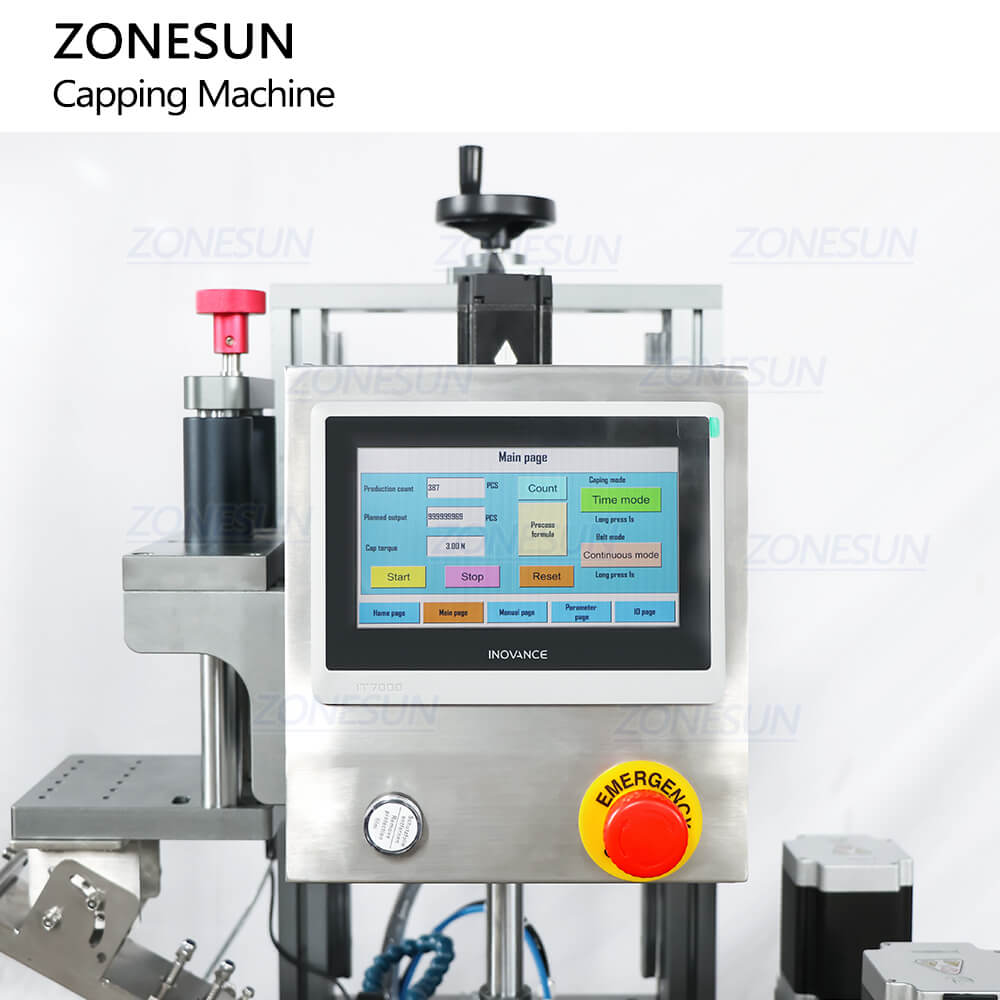

Equipped with touch screen control panel, it shows working data more visually and help operator to watch working status in real time.Different kinds of operation language can be customized as operation need.

Work with cap elevator, it is easier to pour bottle caps, and the machine will arrange caps orderly and supply them time in time.This saves working labor and reduce production error.

The bottle clamping structure can fixed bottles during capp. This capping machine is controlled by servo motor, it has higher capping accuracy.

The electric eye is used to detect passing by bottles, it will send the signal to machine system and control the machine to work automatically.

The bottle guiding structure can help to transport bottles stably, it can prevent bottles from falling down during capping.