ZS-AFC17 Automatic Monoblock Small Glass Perfume Vial Filling Capping Machine

ZS-AFC17 Automatic Monoblock Small Glass Perfume Vial Filling Capping Machine

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

- Local Service Location (Romania /Serbia /Kazakhstan/Mexico/Indonesia)

Click  For Video

For Video

This filling capping machine is equipped with ceramic pump which is suitable for filling small volume liquid and has high filling accurately.It is equipped with bottle umscrambling structure, can put bottles vertically into the rotary plate and realize automated production.This is suitable for perfume vial.

Parameter

Machine model:ZS-AFC17

Voltage:AC220V/380V, 50F 60Hz

Power about:5.5KW

Filling pump:Ceramic Pump

Number of filling heads:2

Working speed:About 1500 BPH

Recommended filling volume:5-6ml

Filling accuracy:±0.58ml

Air pressure:0.6-0.8MPa

Machine size:About 2060*1550*1710mm

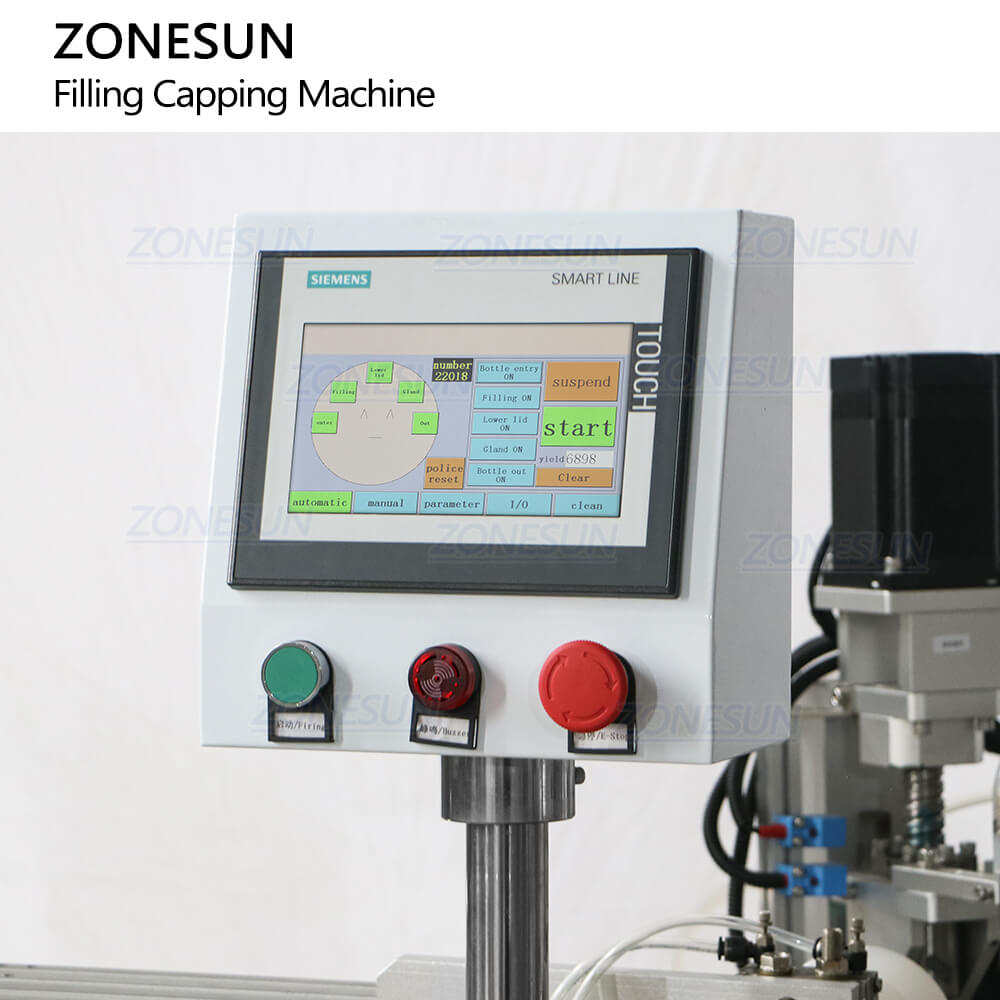

The touch screen control panel makes working data visual, this is more convenient when watching machine working status and good for new operator to debug the machine.Different kinds of language can be customized as needed.

Equipped with bottle grouping structure, this can put bottles onto conveyor one by one, make the flling and capping work can be processed smoothly. it can save working labor and reduce production error.

Designed with bottle standing structure, this can help to put bottles vertically into rotary plate and realize the automated bottle conveying.It is suitable for vials that can not stand during transporting.

Equipped with vibratory bowl sorter, it can unscramble bottle caps automatically and transport bottles caps to the cap pressing structure.With this, it can improves working efficiency.

Single or double filling nozzles can be customized as production need.The small filling nozzle can prevent liquid spraying out during filling and improves filling accuracy.Equipped with ceramic pump, they are suitable for filling small volume liquid.

The capping structure is designed for compressing bottle caps after the electric eye detect bottles. Different kinds of capping structure can be customized according to caps type.

The bottle clamping structure can imitate human hands to take bottles out of fixing mold.This can saves working process of collecting bottles.