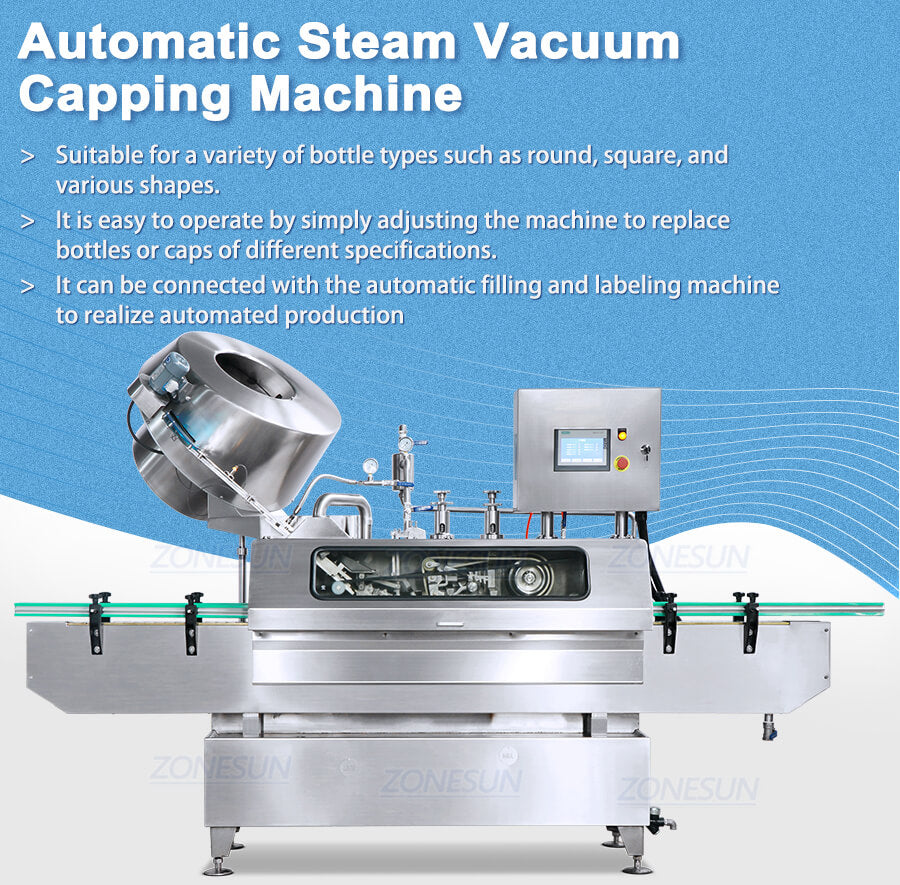

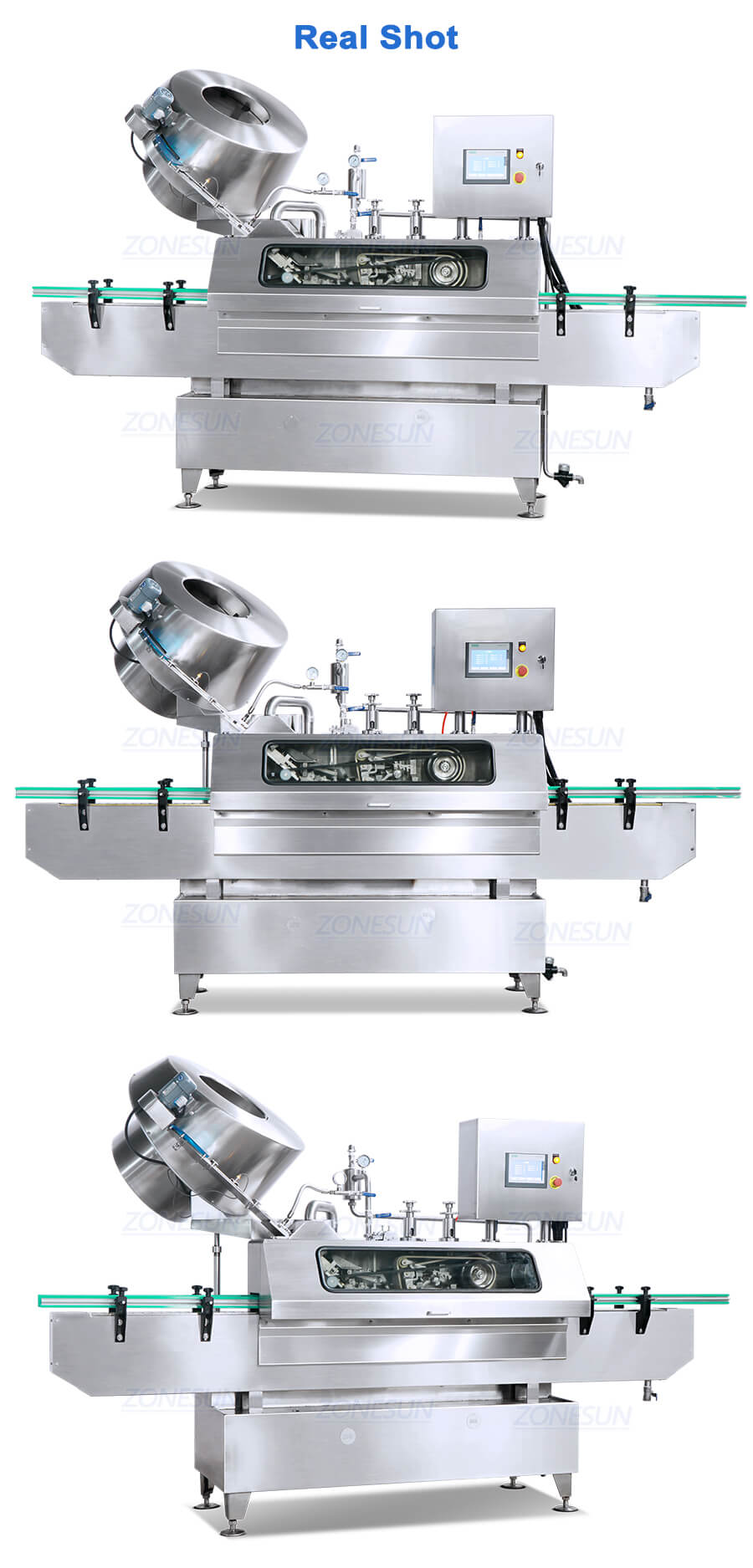

This steam vacuum capping machine is used in the bottling and canning industry to ensure a proper and hermetic seal on containers. Steam is injected into the headspace (the small space between the product and the top of the container) and this causes the air in the headspace to expand and be forced out of the container.It is widely used in food, beverage industries.

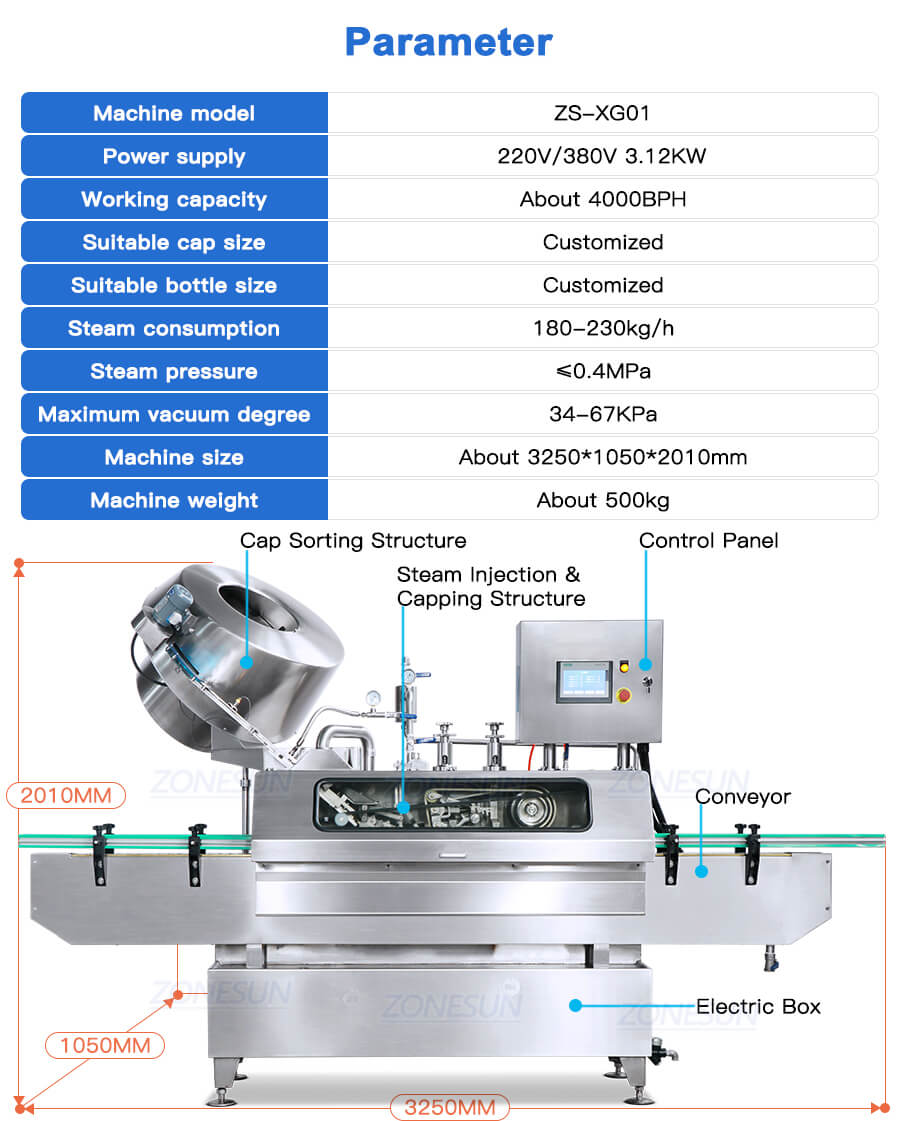

Parameter

- Machine model:ZS-XG01

- Power supply:110/220V 50-60HZ 3.12KW

- Working capacity:About 4000BPH

- Suitable cap size:Customized

- Suitable bottle size:Customized

- Steam consumption:180-230kg/h

- Steam pressure:≤0.4MPa

- Maximum vacuum degree:34-67KPa

- Machine size:About 3250*1050*2010mm

- Machine weight:About 500kg

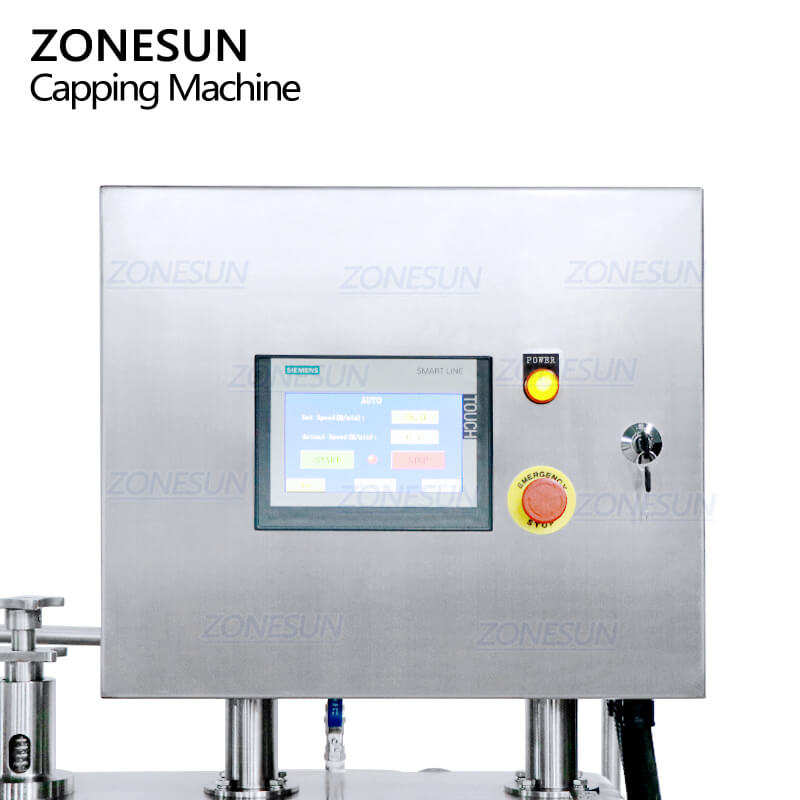

Equipped with PLC touch screen control panel, customizable interface shows machine working data more intuitively. It is also equipped with emergency stop button, which can ensure safety operation

The electric rotation cover sorting method is adopted, the working noise is lower, and the cover sorting is smoother, which can greatly improve the working efficiency of the machine

The electric eye can detect metal twist off caps and realize automated cap feeding in time.The guide rail can be adjusted according to cap size, it is no need to replace extra machine components, this is more convenient and can widen machine application range.

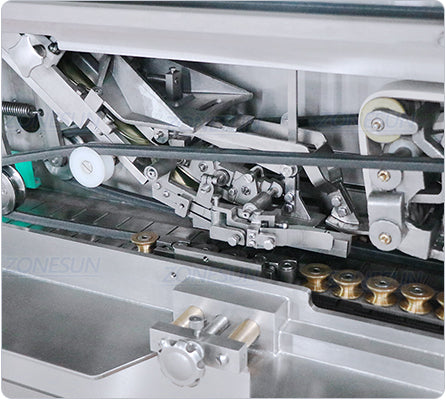

Before sealing, the bottle first passes through the steam injection area, and the high-speed steam is used to replace the normal pressure air in the top space. And later the cover is tightened by two flat belts to complete the sealing.This kind of capping method can ensure working capacity and packaging quality

This machine should work with steam generator, you need to buy this separately.If your product does not require vacuum processing, this machine can still work alone without being connected to the steam generator to achieve the capping function.