Click  For Video

For Video

This packaging system is consist of magnetic pump filling machine, bottle corking machine, heat shrinking machine, and round bottle labeling machine.This packaging system can finish the complete outer packaging production of wine bottles.

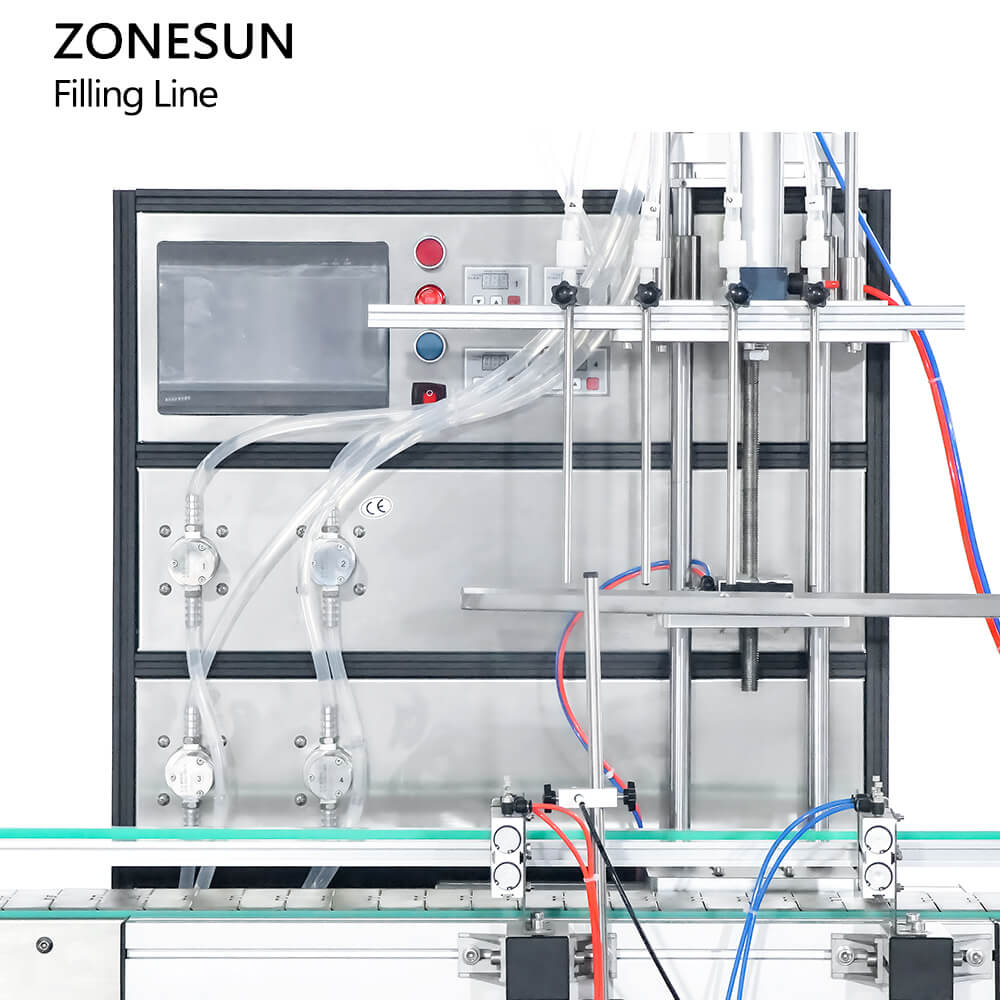

Equipped with diving nozzles, this can prevent liquid from spraying out during filling work.The number of filling nozzle can be customized according to production need.

The filling pump is made of 316 stainless steel magnetic pump, it has low noise and high accuracy, suitable for most of low viscosity liquid.

The vibrating bowl sorting machine will be customized according to cap type and size.This design is used to pre-treat the caps, so that the caps can be neatly entered into the guide rail and transported to the positioning structure, ensuring that the capping work can be processed smoothly

The cap positioning structure work with the cap guiding rail, it is designed for positioning the cap onto the mouth of the bottle and press them into the bottle slightly so that subsequent cap pressing work can be processed smoothly

The heat shrinking machine has film feeding structure, this saves labor of feeding the wine capsule manually.The number of heat shrinking head can be customized according to production need and improve working efficiency.

The labeling structure is consist of three roller, this kind of labeling method is suitable for single side labeling, double sides labeling, wrap-around labeling and has high labeling accuracy.

Extra date coder can be equipped with to realize printing batch number or production date on label stickers and save production process.