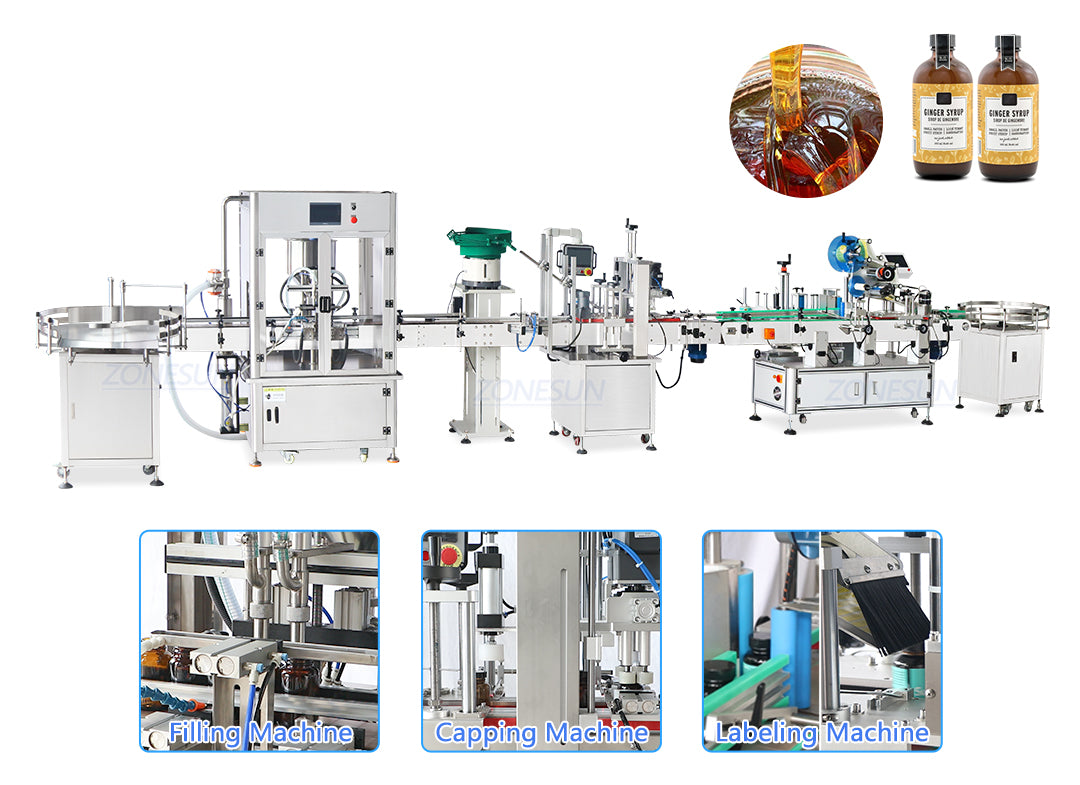

Honey Filling Capping Labeling Machine

Mixing & heating function can be customized

Multi filling heads can be customized as needed

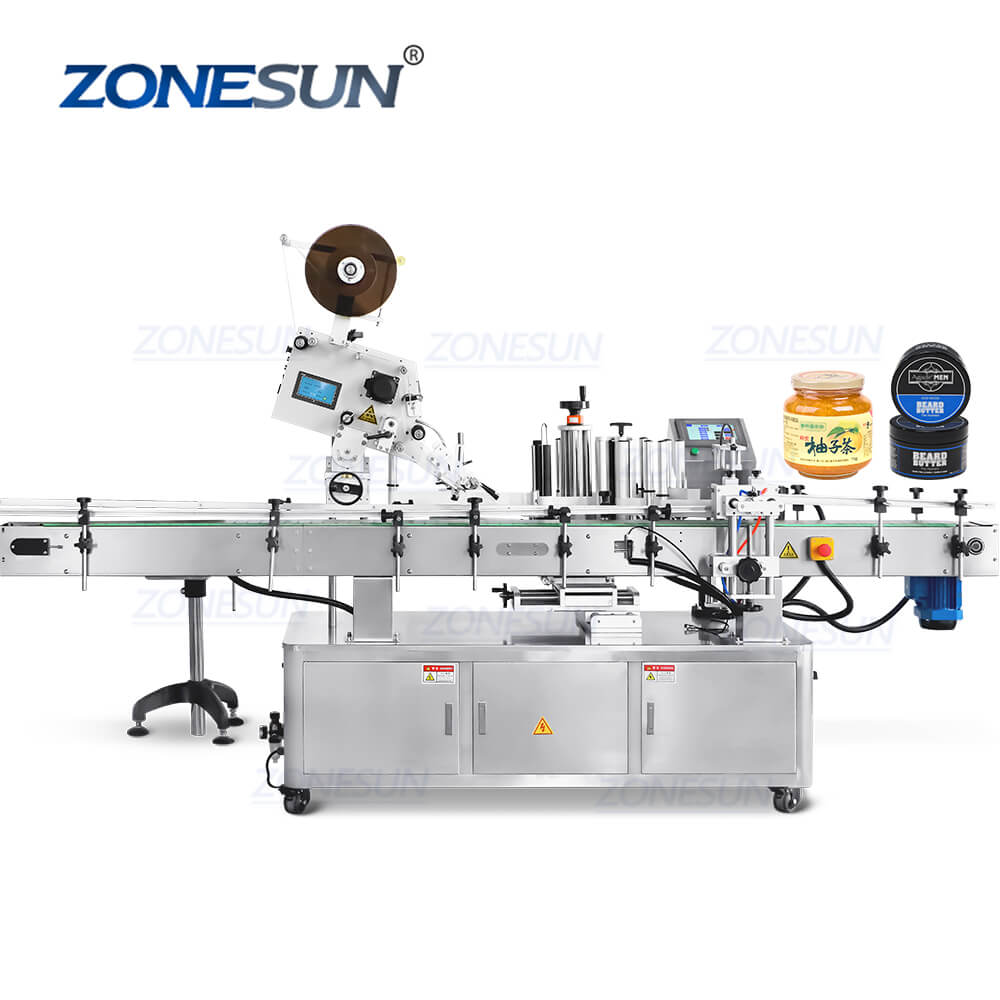

Tamper Evident Labeling

Offer one-stop packaging solution

Offer local service & video chat support

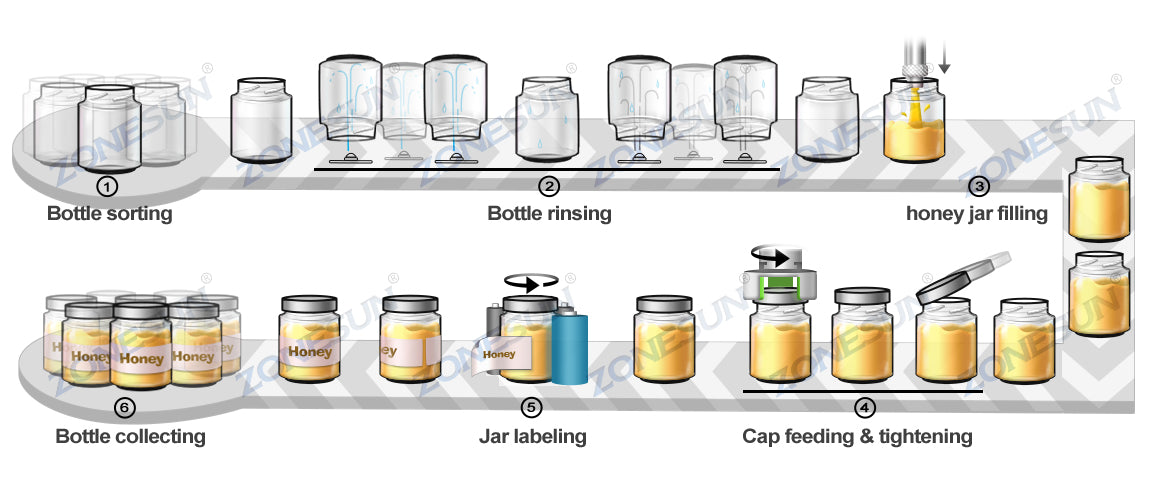

Honey Filling Packaging Process

Honey can be divided into liquid honey and creamed honey, which are two different forms based on their texture and processing: 1. Liquid Honey : This is the most common form of honey, which is in a liquid state at room temperature. It is extracted from the honeycomb and then strained to remove any wax particles. 2. Creamed Honey: Also known as whipped honey, spun honey, or churned honey, this form of honey has a smooth, spreadable consistency. Creamed honey is produced by controlling the crystallization process. Small seed crystals are added to liquid honey and then the mixture is stored at a cool temperature, which encourages uniform crystallization. The result is a honey that is thick and creamy, making it easy to spread on bread and other foods. Both types retain the natural flavors and beneficial properties of honey. The viscosity of honey can vary depending on its composition, temperature, and water content. Generally, honey is quite viscous, meaning it flows slowly. At room temperature (around 20°C or 68°F), the viscosity of honey typically ranges from 2,000 to 10,000 centipoise (cP). However, this value can decrease significantly if the honey is heated, making it flow more easily.

Challenge In Filling Honey

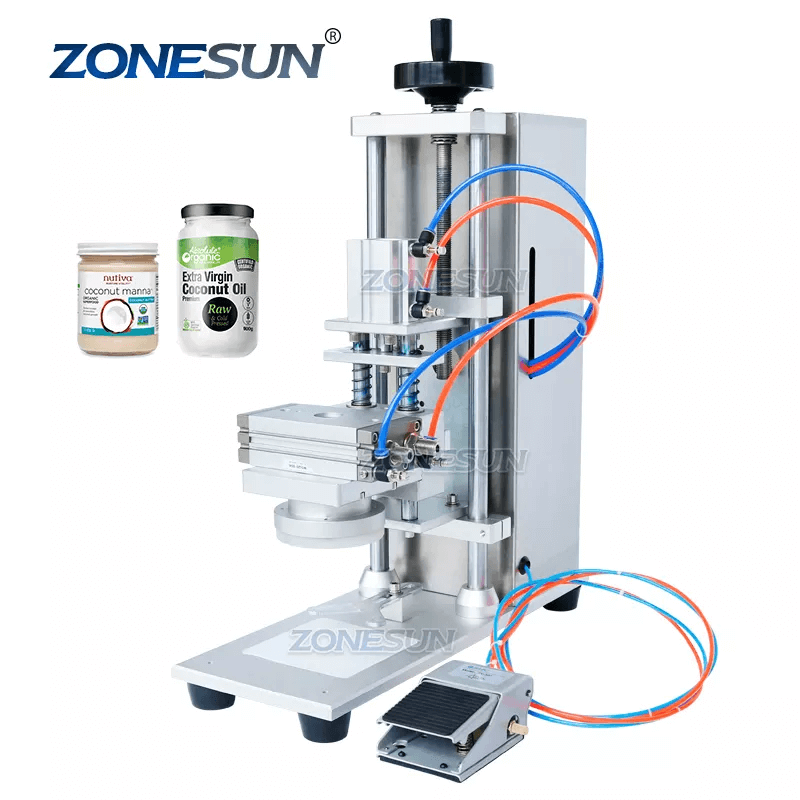

Filling with different sizes of containers

For some small or medium scale honey manufacturers, it is mandatory to be easy to change different sizes of containers with different sizes of caps.We can customized the reasonable packaging solution as their production need and help them as easy as possible to operate machines.

Heating & mixing function

If additives such as flavors, spices, or other ingredients are included, it is important for maintaining consistent honey quality to use mixer to achieve this.Additionally, the heater can reduce the viscosity of honey, makes it easier to handle and pour during the filling process.

Anti-dripping filling

Liquid honey and creamed honey often exhibit high surface tension, and high viscosity can cause the honey to cling to the walls of the filling nozzle or create a stringy flow.As the filling nozzle is withdrawn from the bottles or jars, honey will cling to the nozzle's outer surface, leading to dripping.For solving this problems, we offer the anti-dripping filling nozzles, this can prevent honey dripping efficiently.

Machine material and working space

Equipment for honey production is usually required to withstand high temperatures, and the material of the machine needs to be customized into food-grade stainless steel to ensure safety during the production process. Also, some small and medium scale honey manufacturers may have not enough working space. ZONESUN can provide packaging machinery that meets production requirements according to customer needs.