Fruit Jam Filling Line

Mixing & heating function can be customized

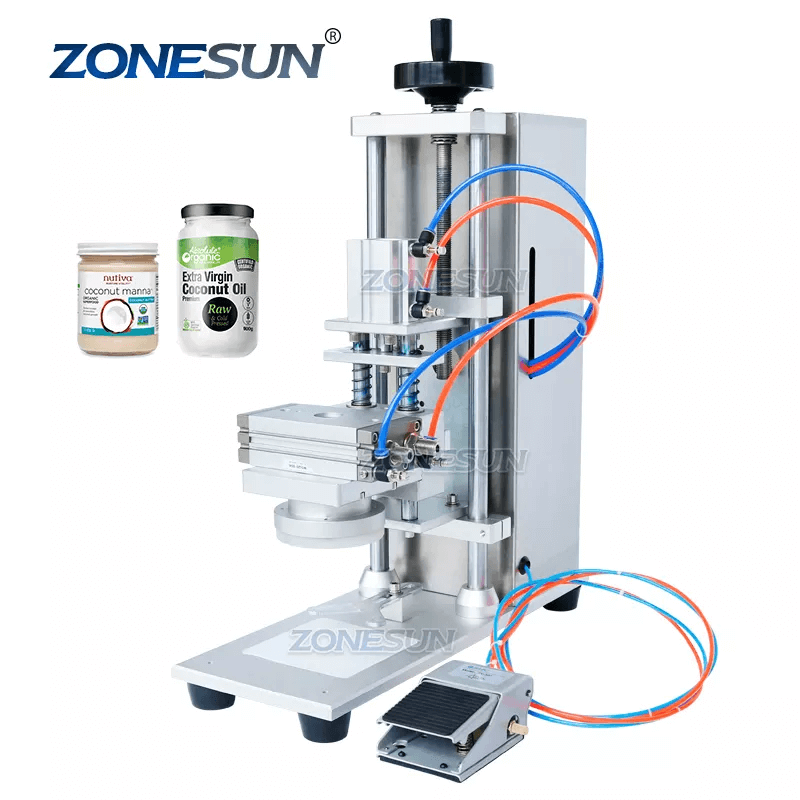

Multi filling heads can be customized as needed

Bottle rinsing machine can clean bottle inside

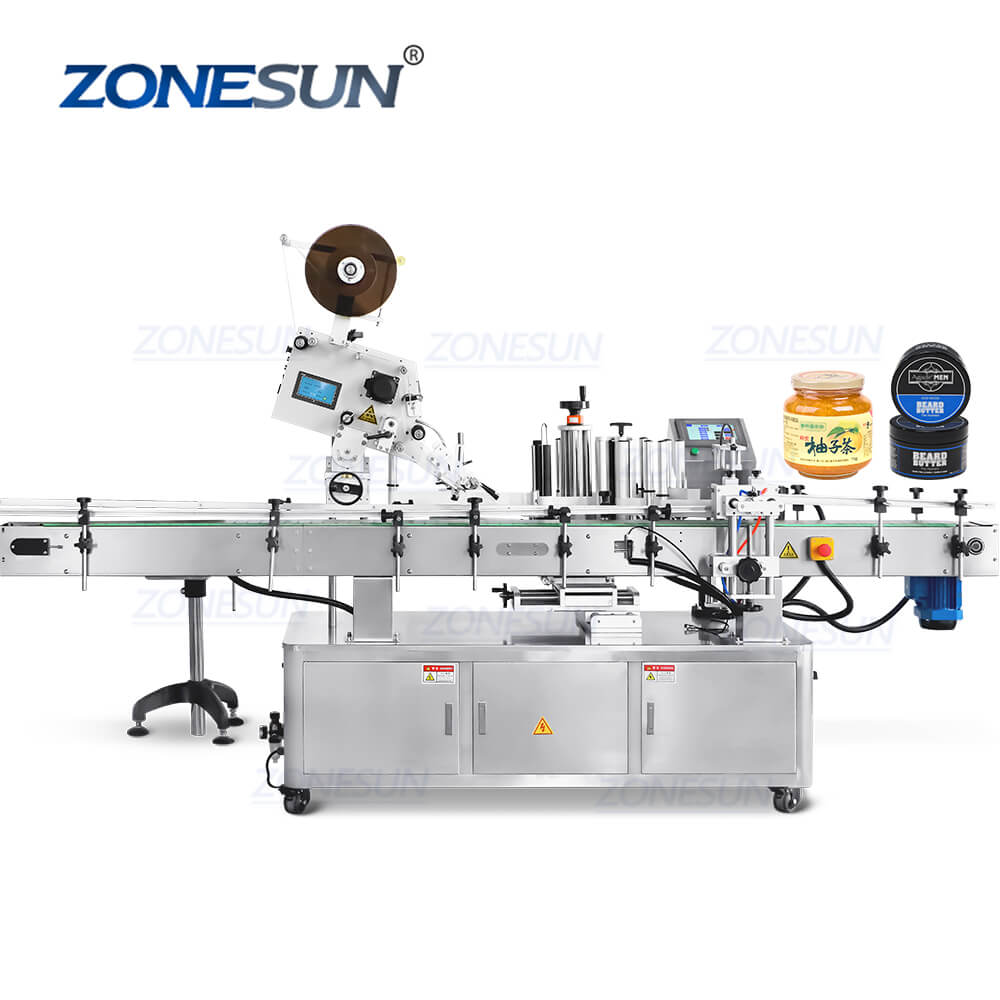

Offer one-stop packaging solution

Offer local service & video chat support

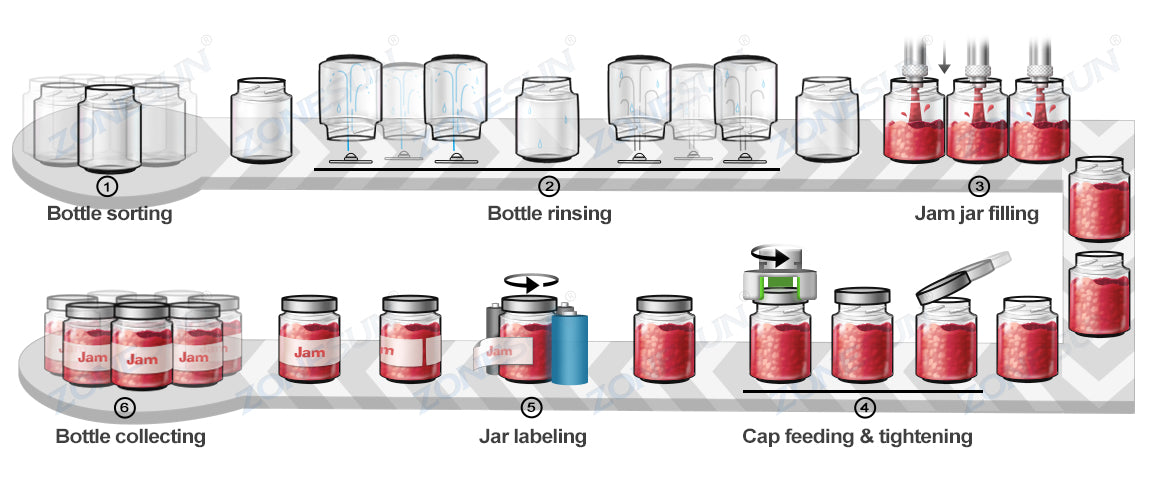

Jam Filling Packaging Process

Fruit jam is a sweet spread made by cooking fruit with sugar to thicken it into a thick, spreadable consistency. It typically contains fruit pulp or pieces along with sugar, pectin (a natural thickening agent found in fruit), and sometimes lemon juice or other flavorings for taste.They are usually packed by glass jar, but they also can be packaged in sachets due to their convenience, portion control, and on-the-go usability, providing pre-portioned servings ideal for travel and reducing food waste.Generally, fruit jam has a relatively high viscosity, typically ranging from around 1,000 cP to 10,000 cP or more.

Challenge In Filling Jam

Uneven filling & dripping

Jam viscosity may change with time or temperature fluctuations. This inconsistency can affect the accuracy and uniformity of filling. To solve this problem, we usually equip the storage hopper of the filling machine with an mixer or a pre-processing machine with mixing function (like mixing tank) to pretreat jam before filling.The heater is also optional.These can ensures jam will be filled evenly and accurately.Additionally, Viscous materials often exhibit high surface tension, and high viscosity can cause the jam to cling to the walls of the filling nozzle or create a stringy flow.As the filling nozzle is withdrawn from the container, jam will cling to the nozzle's outer surface, leading to dripping.For solving this problems, we will customized the anti-dripping filling nozzles, this can prevent jam dripping efficiently

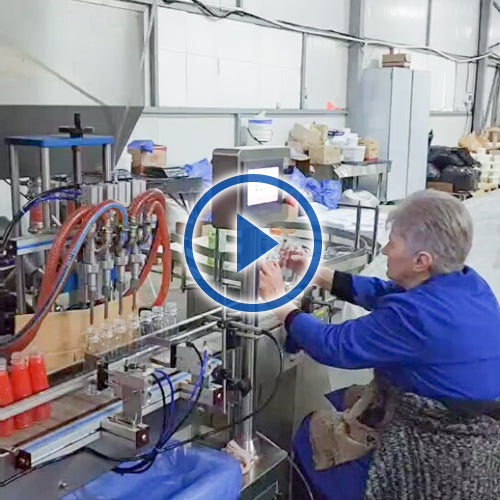

Hard to clean

Jam can leave stubborn residue on the filling machine, making cleaning a demanding task. The thick consistency and spice content of the jam may require thorough disassembly, specialized cleaning agents, and extensive cleaning procedures to ensure proper hygiene and prevent cross-contamination.At the same time, we designed a piston pump filling machine that is easier to clean.Click below video to know more details.(This function is only for this customized filling machine. If you need it, please let us know before placing an order.)

Machine material

Equipment for jam production is usually required to withstand high temperatures, and the material of the machine needs to be customized into food-grade stainless steel to ensure safety during the production process. ZONESUN can provide packaging machinery that meets production requirements according to customer needs.

Fruit grain blockage

Some jam contain small fruit grain. These particles can cause blockages or clogging in the filling machine.To solve this problem, we need to customize the filling pump, filling nozzles as well as filling hose. Take an example, for the piston pump, we will customized the rotary valve for larger pepper granule