This auger powder packaging machine features high-precision SUS304 stainless steel construction for durability and hygiene, delivering efficient and accurate filling for powders like milk powder, coffee, and spices. With a production speed of 20-60 BPM, it ensures precise dosing, minimal waste, and customizable sealing options (back seal, three-side, or four-side). Additionally, it supports customizable nitrogen filling into the bag increases food safety. Ideal for food, pharmaceutical, and chemical industries, this machine guarantees speed, accuracy, and reliability to optimize your packaging process.

Parameter

- Machine model: ZS-FM380

- Machine voltage: 220/380V 50-60HZ

- Machine power: 2600 W

- Suitable film: OPP/CPP OPP/PE NILO/PE PE

- Weighing method: Auger weighing

- Filling range: 1-350 g

- Package speed: 20-60 bags/min

- Width of film: Max 320 mm

- Size of package bags: (W)14-150 mm*(L)50-200 mm

- Sealing method: Back side/Three sides/Four sides

- Machine dimension: About 860*700*1700 mm

- Machine weight: About 250 kg

Operation Panel

Easily adjust packaging weight, bag length, production speed and other parameters to meet different production needs.

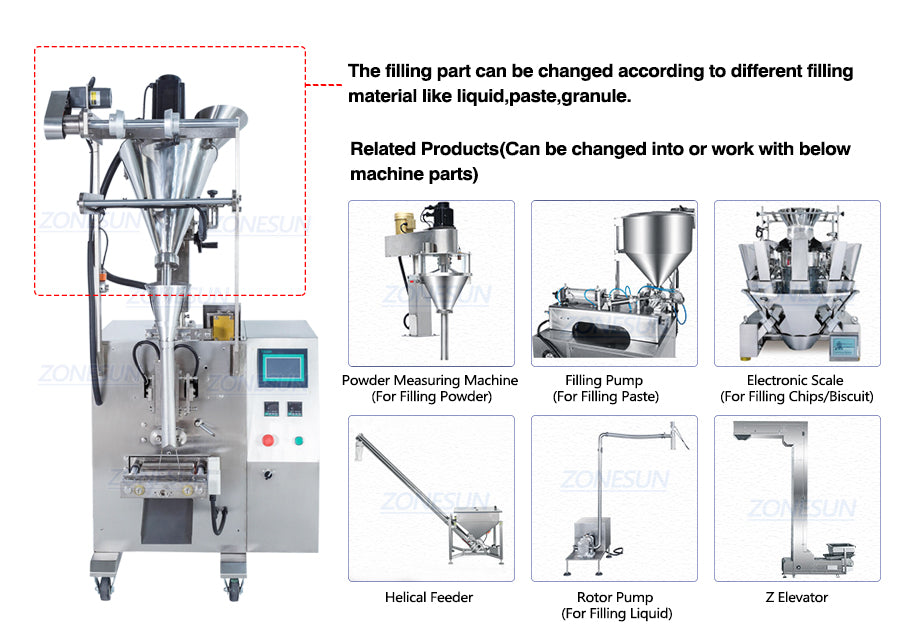

Auger Filling Structure

The agitator blades can ensure smooth filling and can adjust the filling volume to ensure accurate filling. The screw can be customized according to different filling volumes.

Bag Forming Sealing Structure

Heat sealing system ensures tightness and prevents powder leakage or contamination. Supports customized tear notch and nitrogen filling function.

Coding Structure

Support print production date, batch number, shelf life and other information on the packaging bag.

Screw Feeder

Ensures a continuous powder supply for smooth packaging operation, while the electric eye detection prevents material overflow