This packaging system is consist of servo gear pump filler, f-style bottle capper, single side labeler to realize automated small or medium scale production of engine oil.

Parameter

Servo Gear Pump Filling Machinery

- Machine model: ZS-VTGP8D

- Machine voltage: 220/380V 3KW

- Filling range: 5-10L

- Working capacity: 8-16 BPM(based on filling volume)

- Filling pump: Gear Pump

- Drive mode: Servo System

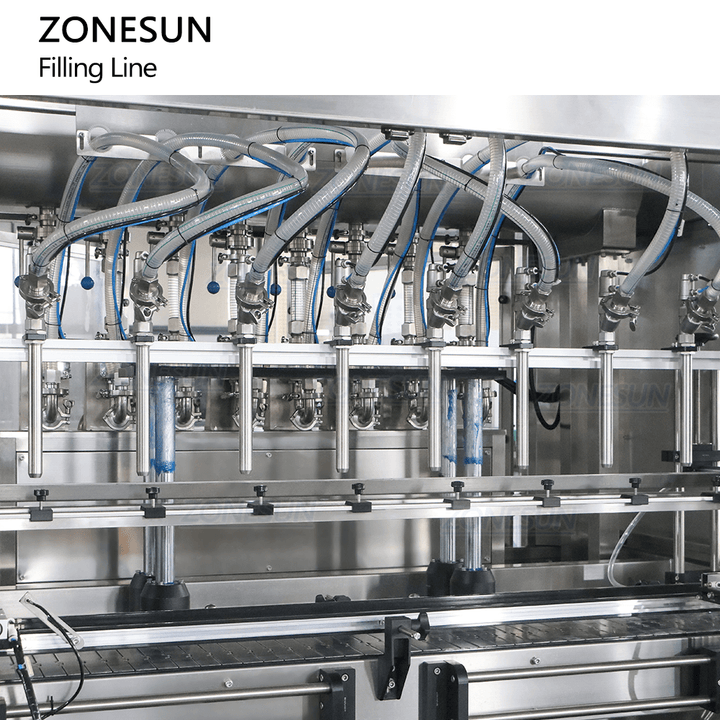

- Filling nozzle quantity: 8

- Air consumption: 4kgs*30L

- Machine size: About 5800*1730*2550 mm

Bottle Capping Machine

- Machine model: ZS-XG441F

- Machine voltage: 110/220V 50-60HZ 2KW

- Suitable cap size: 30-120 mm(Can be customized)

- Suitable bottle height: Customized

- Air pressure: 0.7 MPa

- Working capacity: 5-15 BPM

- Machine size: About 5000*1680*2350 mm

Flat Bottle Single Side Labeling Machine

- Machine model: ZS-TB600R

- Machine voltage: 110/220V 50-60HZ 1500W

- Labeling speed: About 40-100bottles/min(depending on bottle and label size)

- Suitable product Size: About 30-200 mm(H)*12-100 mm(W)

- Label size: 20-300mm(W)*15-100 mm(H)

- Labeling accuracy: ±1 mm

- Label roll inner diamete: φ75 mm

- Label roll outer diameter: φ350 mm

- Machine size: About 3030*1050*1540 mm

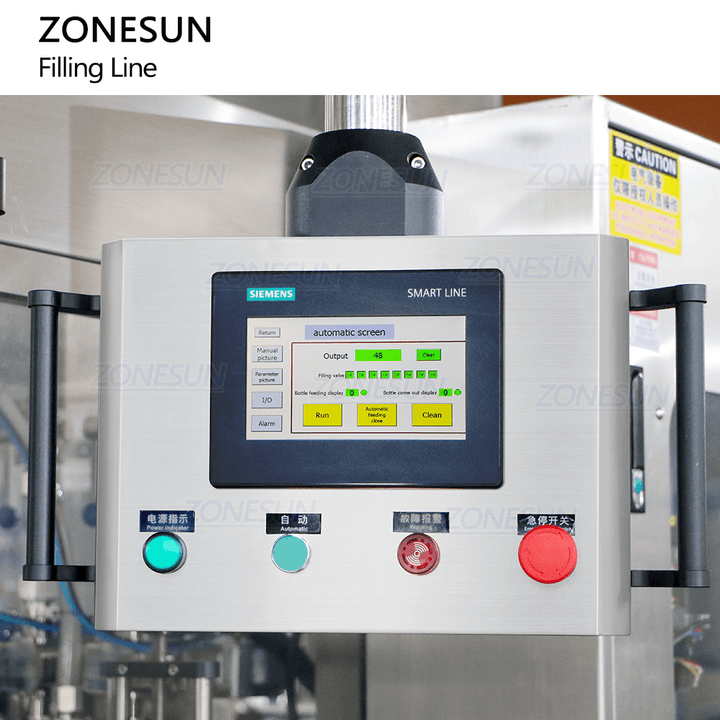

PLC Control Panel

Filling volume can be set easily, customizable interface makes machine debugging more conveniently.

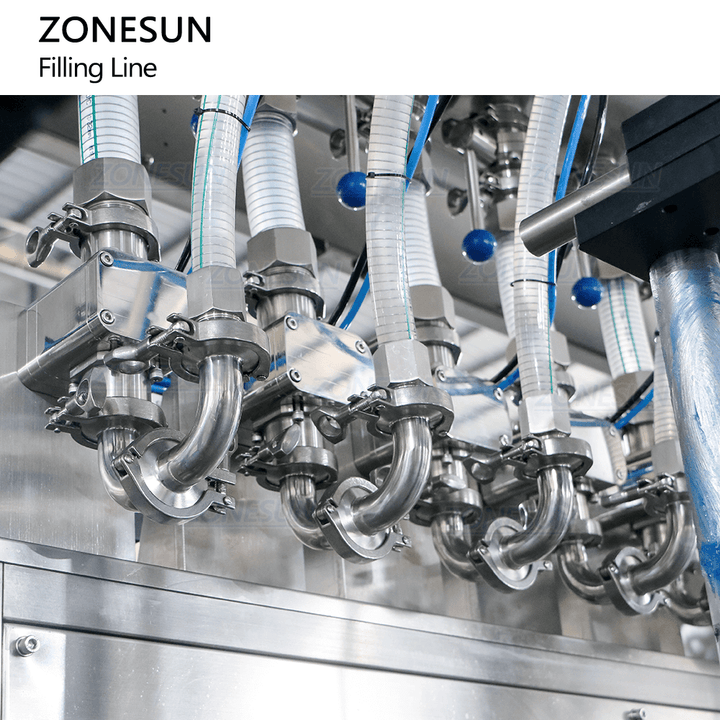

Filling Nozzles

Multi filling heads can be customized, anti-dripping structure ensures production quality

Servo Gear Pump

Filling work is controlled by servo gear pump,it has higher filling accuracy.

Feeding Pump

Can supply filling material in time once the liquid level sensor detects the material shortage.

UV Sterilization

Helps to kill bacteria, viruses, and other microorganisms. The cap elevator can lifts caps and moves them to the capping area.

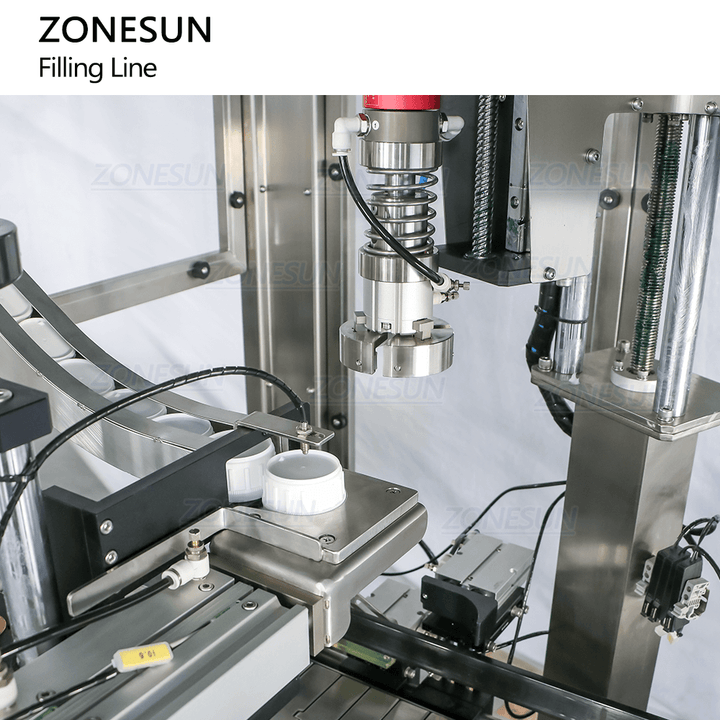

Capping Conveying & Capping Structure

Processes of passing and tightening caps are controlled by servo motor, capping torsion can be controlled more accurately.

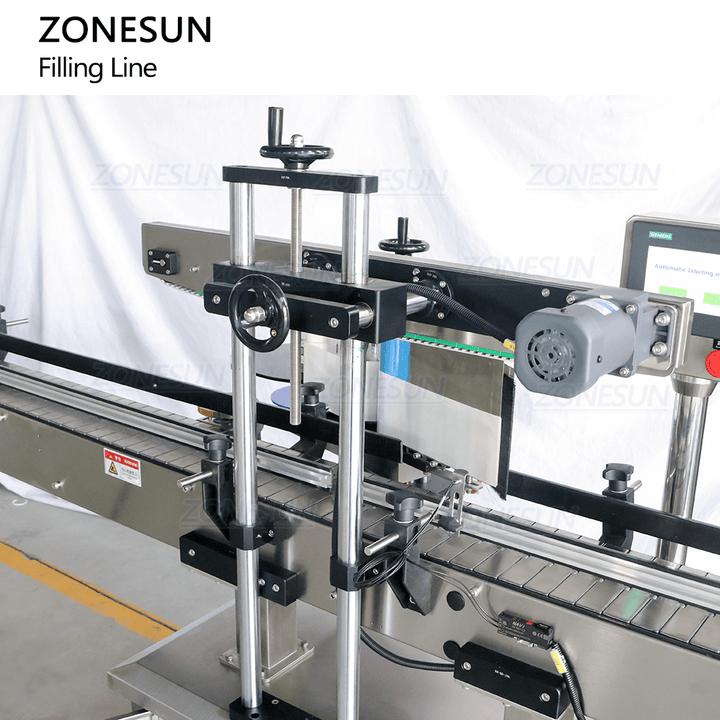

Labeling Structure

Suitable for single side labeling on flat bottles, working height can be adjusted as production need.

Electric Eye

Detect passing by bottles and control the machine to realize automated work.

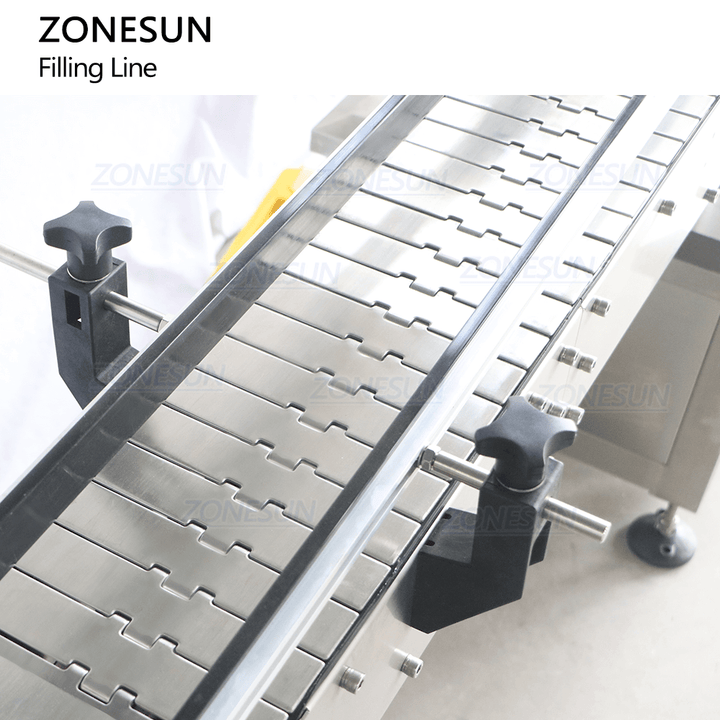

Chain Conveyor

Length and width can be customized as production need, it has large weight capacity.