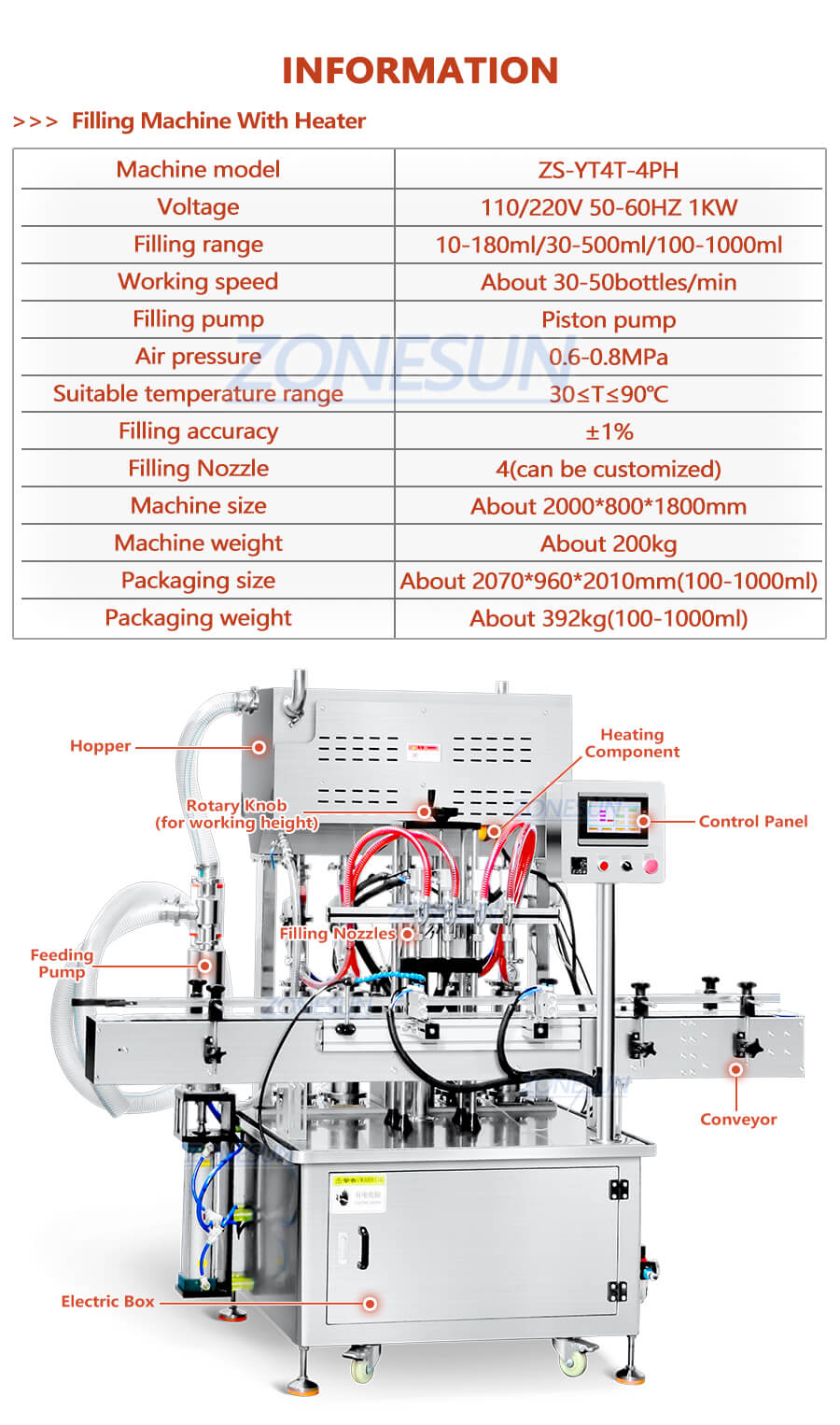

ZONESUN ZS-FAL180B10 Automatic Piston Pump Chili Sauce Chutney Fruit Jam Jar Metal Lug Twist Off Bottle Filling Steam Vacuum Capping Machine Production Line

Earn 0 points on this purchase.

- One Year Warranty

- User Manual

- One-to-one Video Chat Support

- Install & Debug Video

- Custom Package Solution

- Local Service Location (Romania /Serbia /Kazakhstan/Mexico/Indonesia)

This filling production line is consist of piston pump filling machine, and steam vacuum capping machine. Heating and mixing function can be customized for filling material pretreatment. This filling system is suitable for packaging hot sauce, honey, tomato sauce, peanut butter.

Parameter

Piston Pump Filling Machine With Heater

- Machine model: ZS-YT4T-4PH

- Voltage: 110/220V 50-60HZ 1KW

- Filling range: 10-180 ml/30-500 ml/100-1000 ml

- Working speed: About 30-50 bottles/min

- Filling pump: Piston pump

- Air pressure: 0.6-0.8 MPa

- Suitable temperature range: 30≤T≤90℃

- Filling accuracy: ±1%

- Filling Nozzle: 4 (can be customized)

- Machine size: About 2000*800*1800 mm

- Machine weight: About 200 kg

- Packaging size: About 2070*960*2010 mm(100-1000 ml)

- Packaging weight: About 392 kg(100-1000 ml)

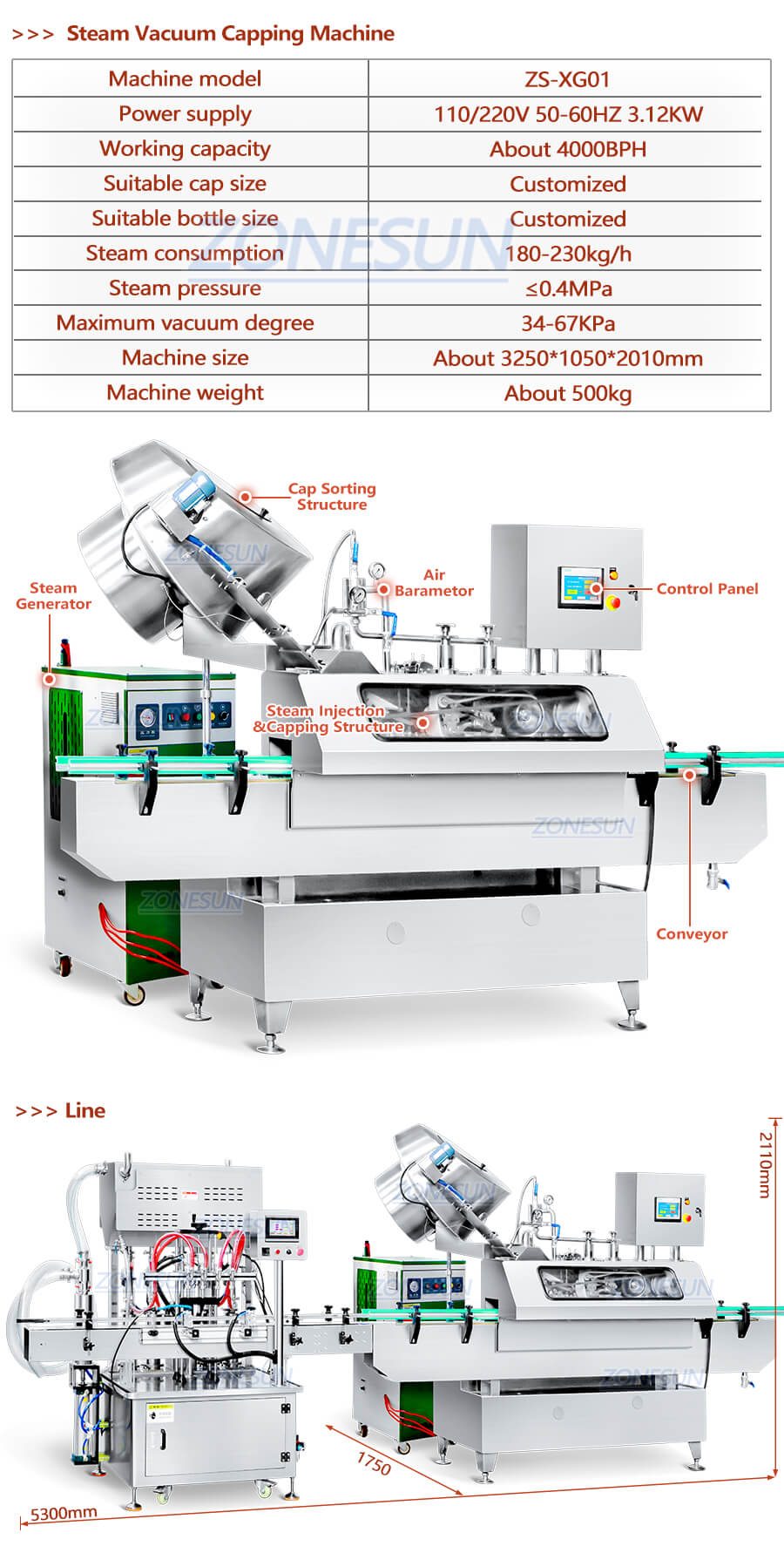

Steam Vacuum Capping Machine

- Machine model: ZS-XG01

- Power supply: 110/220V 50-60HZ 3.12 KW

- Working capacity: About 4000 BPH

- Suitable cap size: Customized

- Suitable bottle size: Customized

- Steam consumption: 180-230 kg/h

- Steam pressure: ≤0.4 MPa

- Maximum vacuum degree: 34-67 KPa

- Machine size: About 3250*1050*2010 mm

- Machine weight: About 500 kg

The touch screen control panel can be customized in different kinds of language for convenient operation.Visual working data makes it easier to adjust the machine in real time.

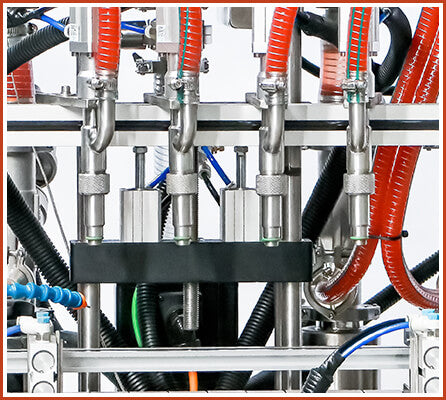

The position of filling nozzle can be adjusted according to bottle size,The quantity of filling heads can be customized to improve working efficiency greatly according to production need.

The filling machine has heating function which can make products remains in a more fluid state, improving its flow properties.Extra mixing function can be customized for the filling material pretreatment.

Made of high quality conveyor belt,the chain conveyor has larger weight capacity, it can transport bottles faster and smoothly,the width and length can be customized as operation need.

The electric rotation cover sorting method is adopted, the working noise is lower, and the cover sorting is smoother, which can greatly improve the working efficiency of the machine

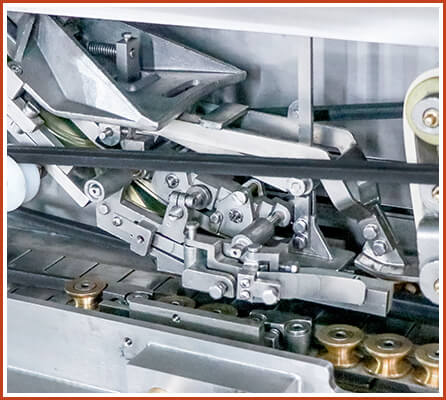

Before sealing, the bottle first passes through the steam injection area, and the high-speed steam is used to replace the normal pressure air in the top space. And later the cover is tightened by two flat belts to complete the sealing.This kind of capping method can ensure working capacity and packaging quality

This vacuum capping machine need to work with steam generator.The steam generators are designed to produce a steady and consistent supply of steam, ensuring reliable operation of the steam vacuum capping machine without interruptions or fluctuations in steam pressure.