This is an automatic coffee capsule filling and sealing machine designed to streamline the production of coffee capsules. This high-speed, dual-station monoblock system features a star wheel rotary design, automating the entire K-cup filling process, including cup placement, coffee powder filling (using auger fillers), lid placement, heat sealing, and cup ejection. It achieves production rates of up to 1,800 cups per hour with precision and efficiency.

Parameter

- Model: ZS-KCFC2

- Power: 2.2 kW

- Voltage: 220V / 380V 50/60Hz

- Speed: 1200-1800 cups/hour

- Fill Range: 2-10 g (customized according to cup capacity)

- Filling Accuracy: 99 %

- Use Air Pressure: 0.5 MPa-0.75 MPa

- Maximum Air Consumption: 0.45 m³/min

- Size: 1200*1100*1900 mm

- Machine Weight: 350 kg

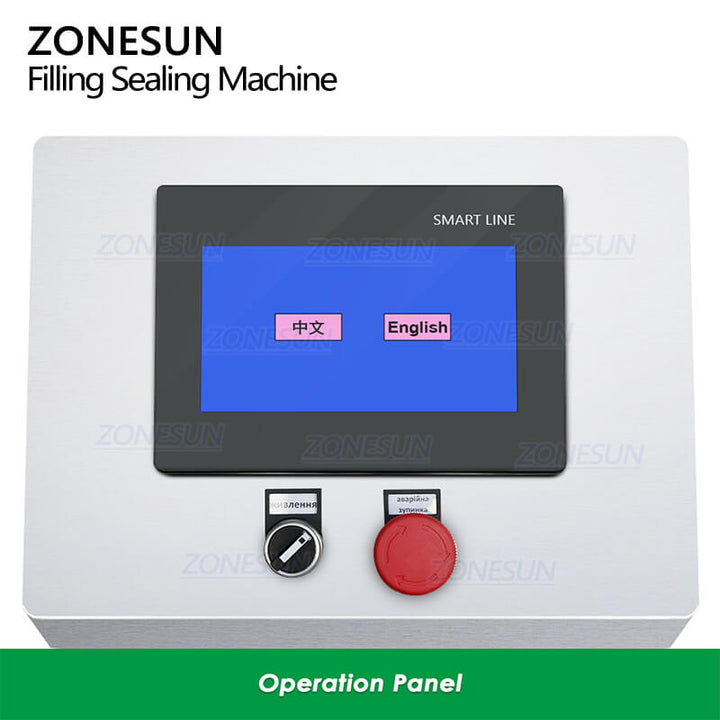

OPERATION PANEL

Adopts touch screen with intuitive interface, allowing parameters to be set quickly and easily. It also supports multiple languages, which is convenient for different users.

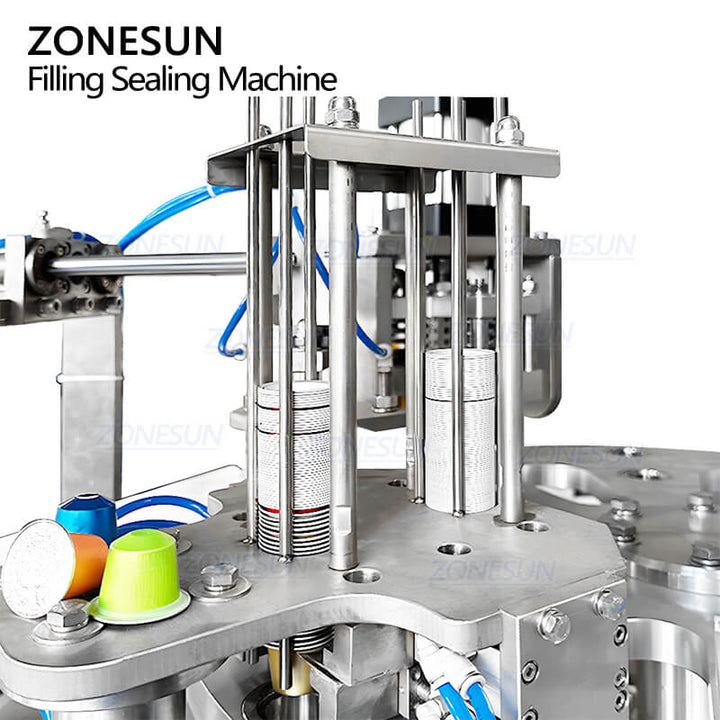

CUP DROPPING

Automatically places cups into rotating molds, simplifying the preparation process and improving the efficiency of the production line.

AUTOMATIC FILLING

Adopts high-precision metering screw to ensure accurate filling. The filling volume is adjustable, and up to 99% filling accuracy can be achieved.

FILM RELEASE

Adopts vacuum suction cups to firmly grasp the sealing film and place it precisely on the top of each cup. It has an intelligent correction function to ensure accurate film placement.

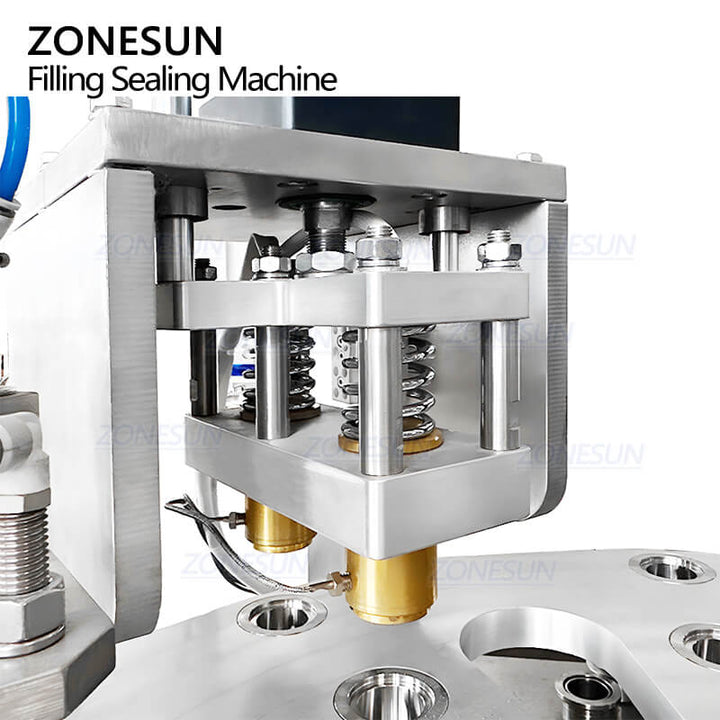

AUTOMATIC SEALING

Contains heating and temperature control components that can be adjusted according to the sealing material used to ensure a tight seal.