Our advanced single-head powder filling and sealing machine automates the entire process, from precise cup feeding and powder filling to secure heat sealing, ensuring consistent quality and high productivity. With an intelligent operation panel, it is ideal for efficient production of hot chocolate pods, coffee capsules in various formats like K-Cup, streamlining your production line for better output and minimal downtime.

Parameter

- Model: ZS-KCFC1

- Power: 3 Phase,220/380 V, 50/60 HZ,1.2 KW

- Air Consumption: 0.1 m³/min

- Air supply: >0.6 Mpa

- Filling Accuracy: ± 0.1 g

- Capacity: About 20 cup/minute

- Filling Weight: 0-20 g

- Weight: 120 Kg

- Dimension: 602*820*1653 mm

OPERATION PANEL

The touch screen interface is intuitive and clear, and simple parameter settings simplify the operation process.

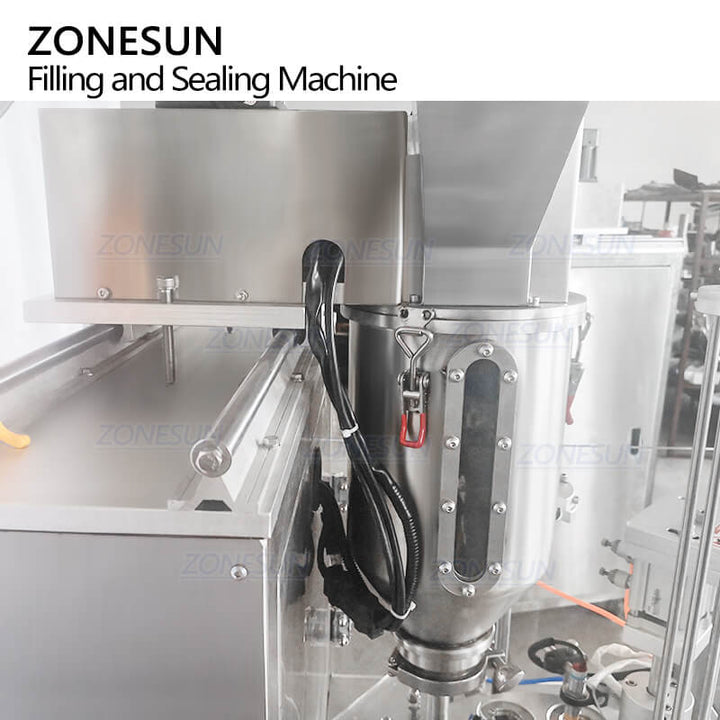

SERVO DRIVEN

High-precision metering screw is used for filling, the filling volume is adjustable, and the accuracy is ±0.2g.

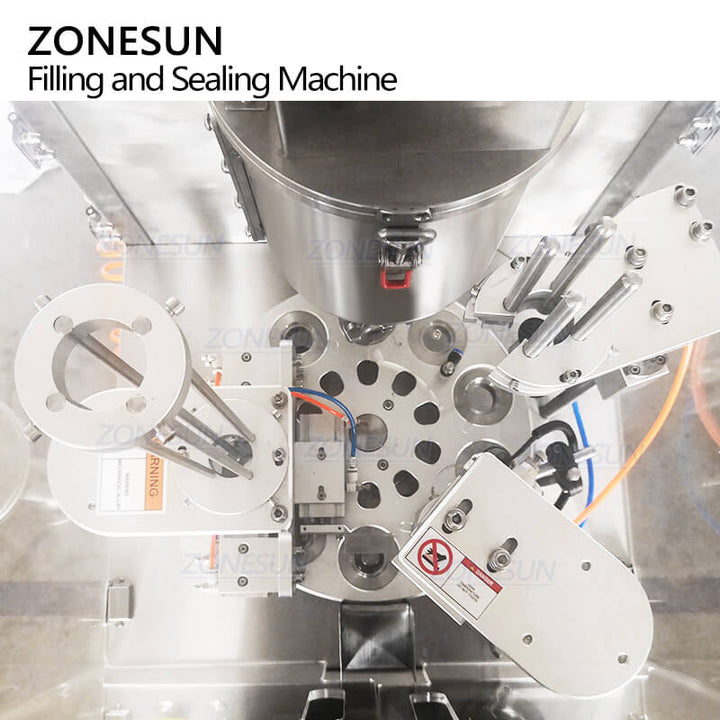

LID FEEDING SYSTEM

The vacuum suction cap positioning device ensures that each cup is capped accurately.

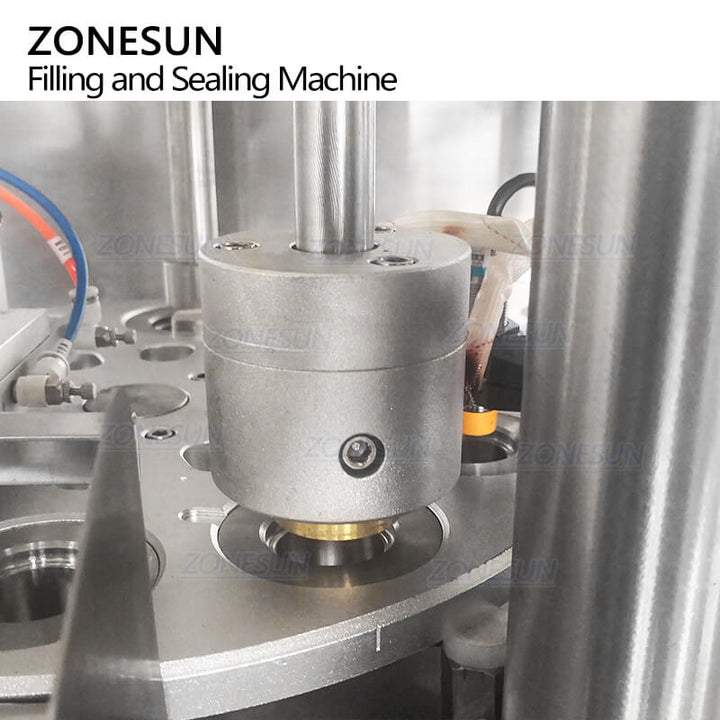

HEAT SEALING

It has consistent temperature control function to ensure even heating, automatic correction mechanism, adjusts the sealing position, and the seal is firm.

TURNTABLE

Made of food-grade 304 stainless steel, corrosion-resistant and easy to clean, compliant with food industry standards.