This packaging system consist of monoblock machine and label applicator. It can finish filling, capping and labeling work at the same time.This packaging system is good for packaging liquid products into roller ball bottles like perfume oil, deodorant etc.

Parameter

Monoblock Filling Capping Machine

- Machine Model: ZS-AFC11

- Voltage: 220V/110V 50-60Hz

- Power: 2500W

- Filling Pump: 316 Stainless Steel Magnetic Pump

- Working Speed: 25-30 bottles/min(depending on bottle size and liquid)

- Max Flow Rate: 4L/min*2(based on water)

- Suitable Bottle Size: Customized

- Bottle Cap Diameter: Customized

- Package Size: About 2040*1660*1650mm

- Package Weight: About 535kg

Labeling Machine

- Model: ZS-TB260R

- Power supply: AC220V 50Hz/60Hz 1000 W

- Labeling capacity(bottles/min): 25-50 bottles/min(depends on bottle size)

- Labeling accuracy(mm): ±1.0 mm

- Suitable Bottle Size: Φ=30-100 mm H=30-200mm

- Label size(mm): (L)20-300 mm (H)12-130 mm(Can be customized)

- Roll inside diameter(mm): Φ76mm

- Roll outside diameter(mm): Φ350mm

- Conveyor Size: 112*2000mm(W)

- Machine size: About (L)2000*(W)820*(H)1380(mm)

- Machine weight: About 180kg

- Packing Size: About (L)2100*(W) 890*(H)1520(mm)

- Package weight: About 250 kg

Control Panel

Touch screen control panel makes parameter setting more intuitively, simple machine operation and debugging.

Filling Capping Structure

Starwheel is customizable based on bottle size, compact machine body saves working space

Filling Structure

Equipped with 316 stainless steel magnetic pumps, it can fill liquid accurately.

Sensor

Each working station has a sensor to detect passing by bottles and realize automated work.

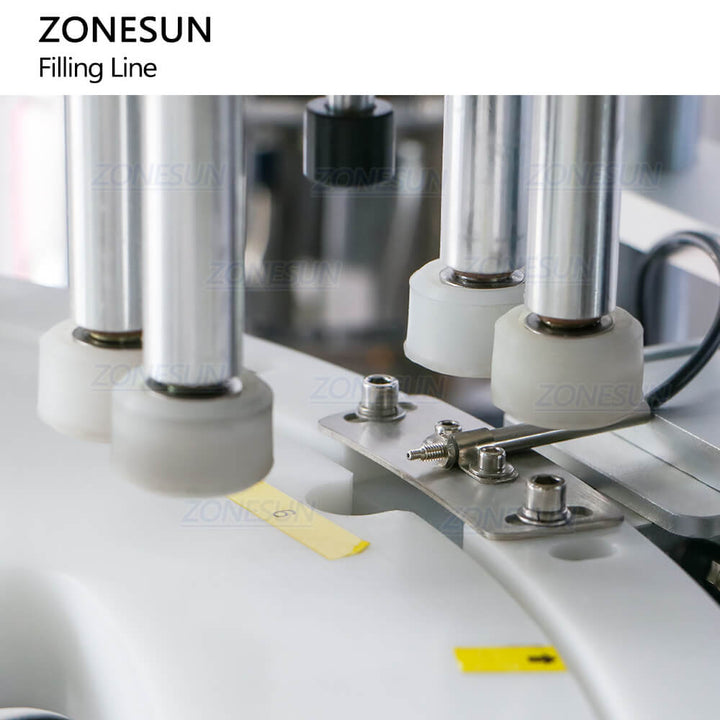

Labeling Structure

Use three rollers to stick labels on bottles, it suits single side, double sides and wrap-around labeling.

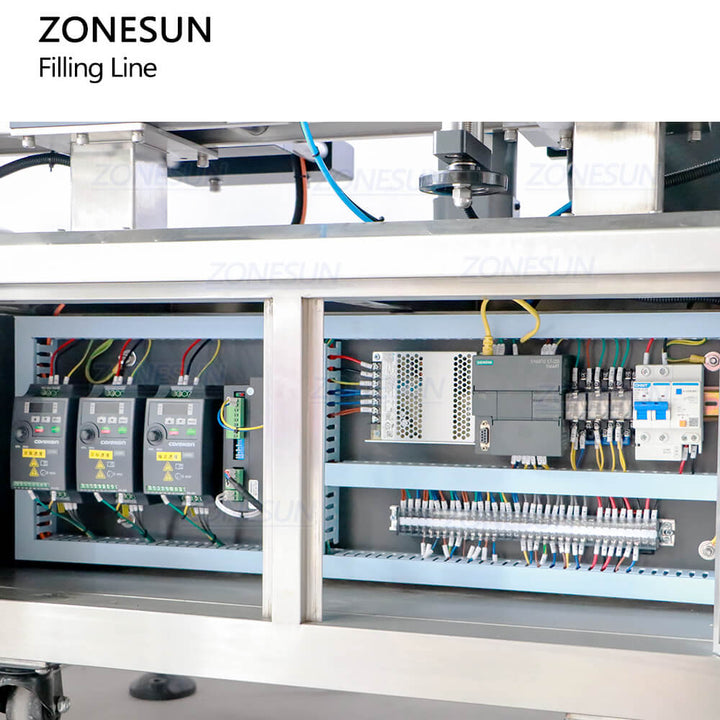

Circuit

Electric circuit are connected neatly, ensures machine work stably.