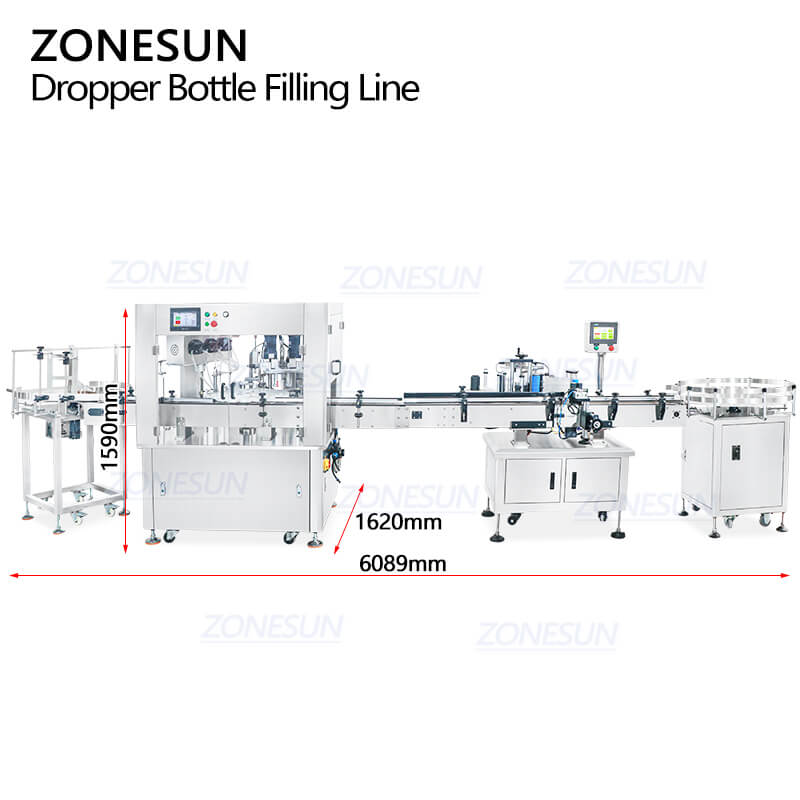

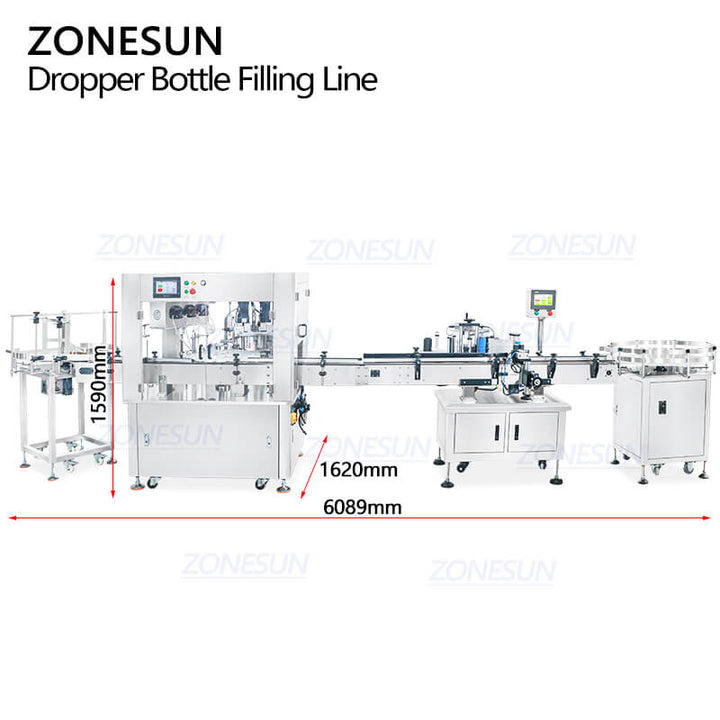

This filling system is designed for packaging small bottles such as cosmetic serums, essential oils, and massage oils, ideal for small-scale production. It includes a monoblock filling and capping machine, labeling machine with date coder, and a bottle sorting machine. The system operates with a cam system, achieving a speed of 25-30 BPM, and utilizes a peristaltic pump for accurate filling with a minimal error of ±0.1 ml. It supports both single and double-side labeling, and features inkjet coding for printing QR codes, logos, and dates on bottles. This compact and efficient system ensures precise and streamlined packaging for small bottle production.

Monoblock Filling Capping Machine Parameter

- Machine model: ZS-AFC45

- Machine voltage: 110/220V 50-60HZ 2.5KW

- Filling pump: Peristaltic Pump

- Filling range: 10-100 ml

- Filling error: ±0.1 ml

- Working capacity: 25-30 BPM

- Suitable bottle size: 20-50 mm*50-110 mm(φ*H)

- Suitable cap size: Φ=21.5 mm (Customizable)

- Air pressure: 0.4-0.6 MPa

- Machine size: About 2205*1620*1590 mm(L*W*H)

- Machine weight: About 700 kg

Labeling Machine Parameter

- Model: ZS-TB260R Labeling Machine

- Power supply: AC 220 V 50/60 Hz 1 KW

- Labeling capacity(bottles/min): 25-50 bottles/min(depends on bottle size)

- Labeling accuracy(mm): ± 1.0 mm

- Suitable Bottle Diameter: Φ30-100 mm H=30-200 mm

- Label size(mm): (L)20-300 mm (H)12-130 mm

- Roll inside diameter(mm): Φ76 mm

- Roll outside diameter(mm): Φ350 mm

- Conveyor Size: 112*2000 mm(W)

- Machine size: About (L)2000*(W)820*(H)1380(mm)

- Machine weight: About 180 kg

- Packing Size: About (L)2100*(W)890*(H)1520(mm)

- Package weight: About 250 kg

Touch Screen Control Panel

Parameter setting will be more convenient, multi kinds of language are customizable as production needs.

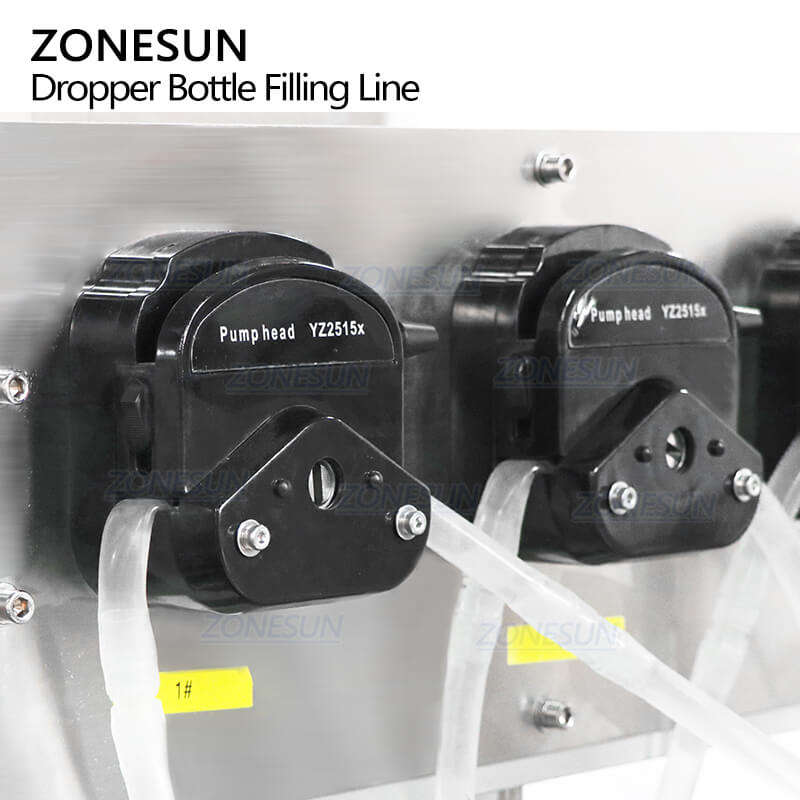

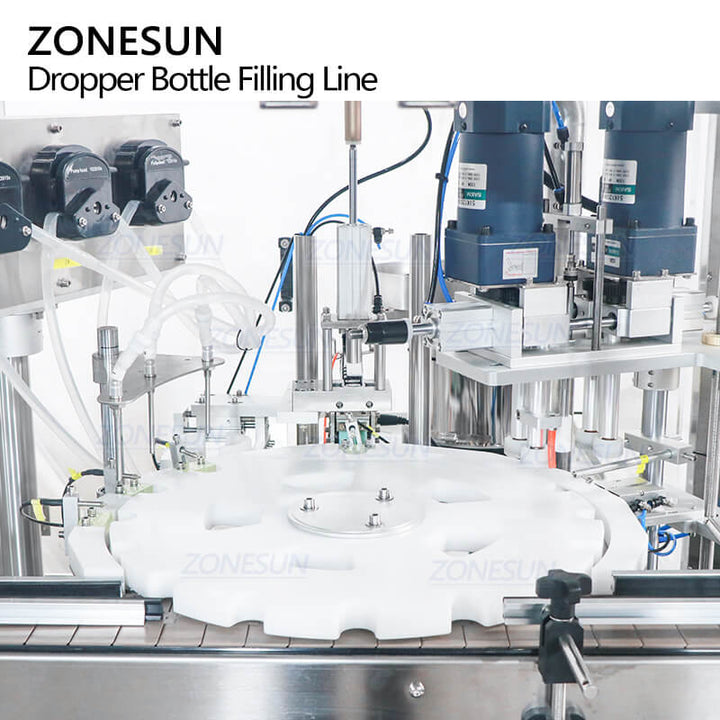

Peristaltic Pump

Liquid only pass through filling hose, it has high filling accuracy and high packaging quality.

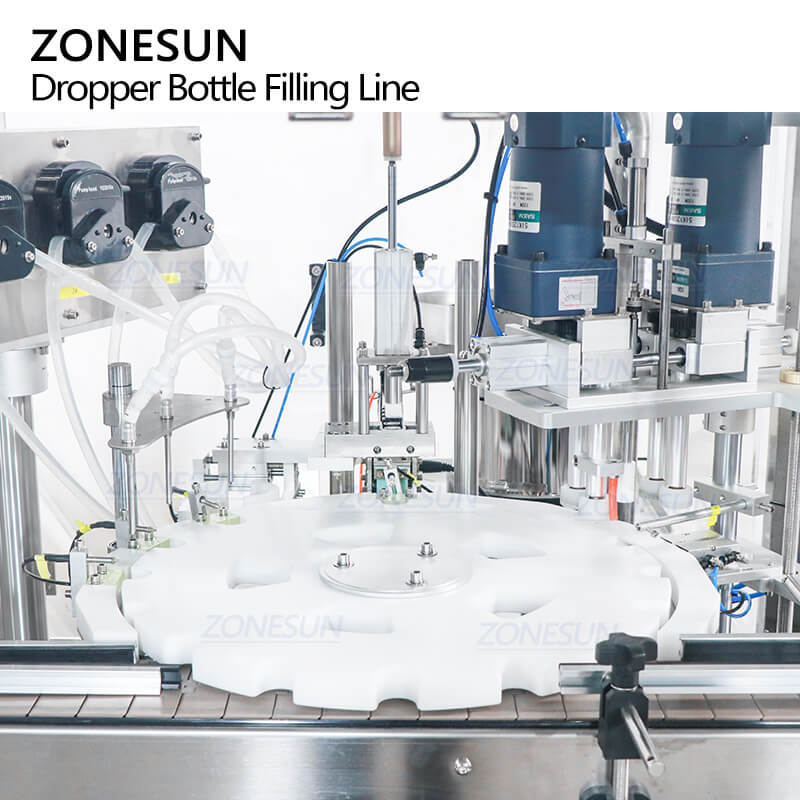

Monoblock Design

Filling, capping placing and capping work are controlled by cam system, it can reach 25-30 BPM.

Vibratory Bowl Sorter

This is customizable as cap size, it can supply caps in time to ensure smooth working.

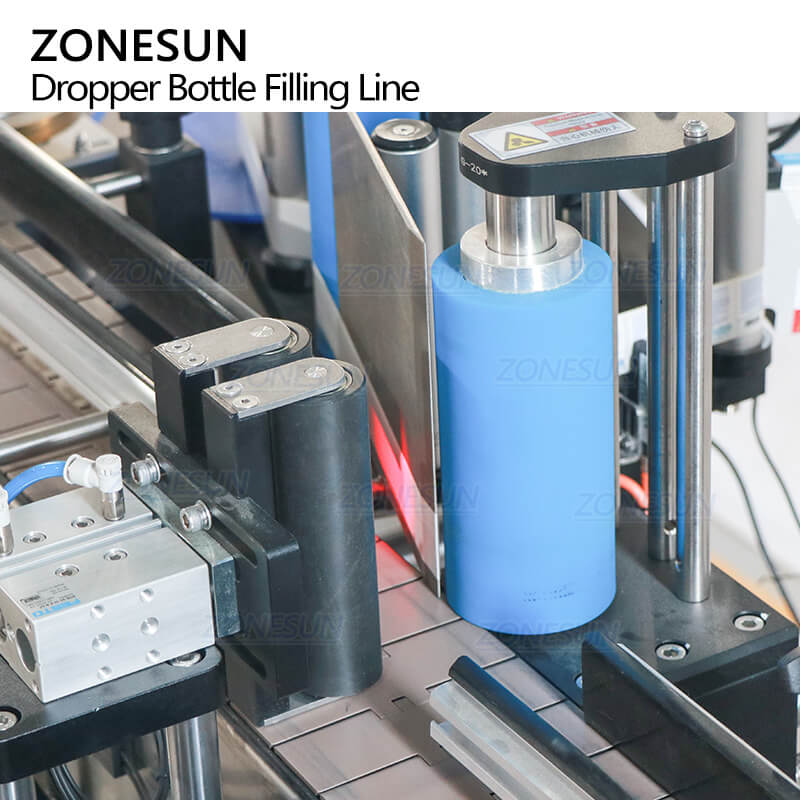

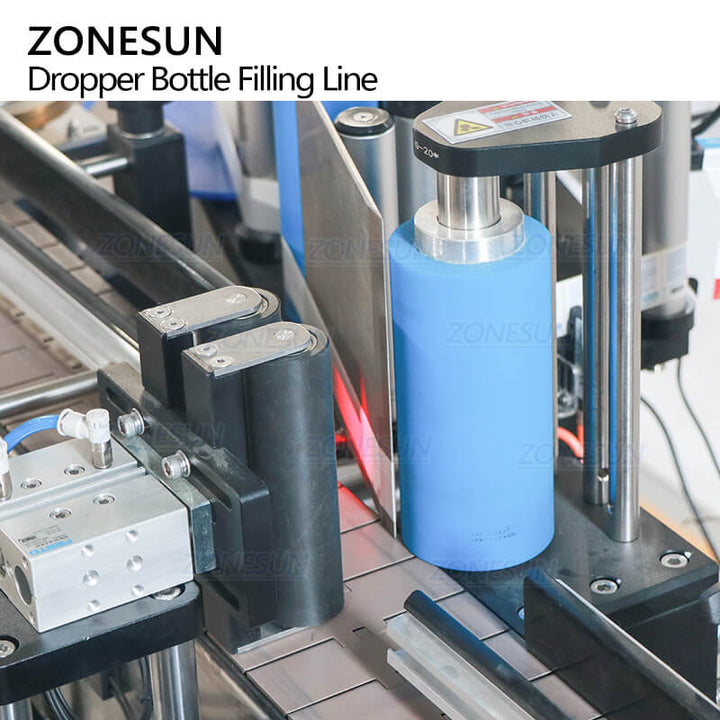

Labeling Structure

Using three-roller labeling structure, it is suitable for single and double sides labeling for round bottles.

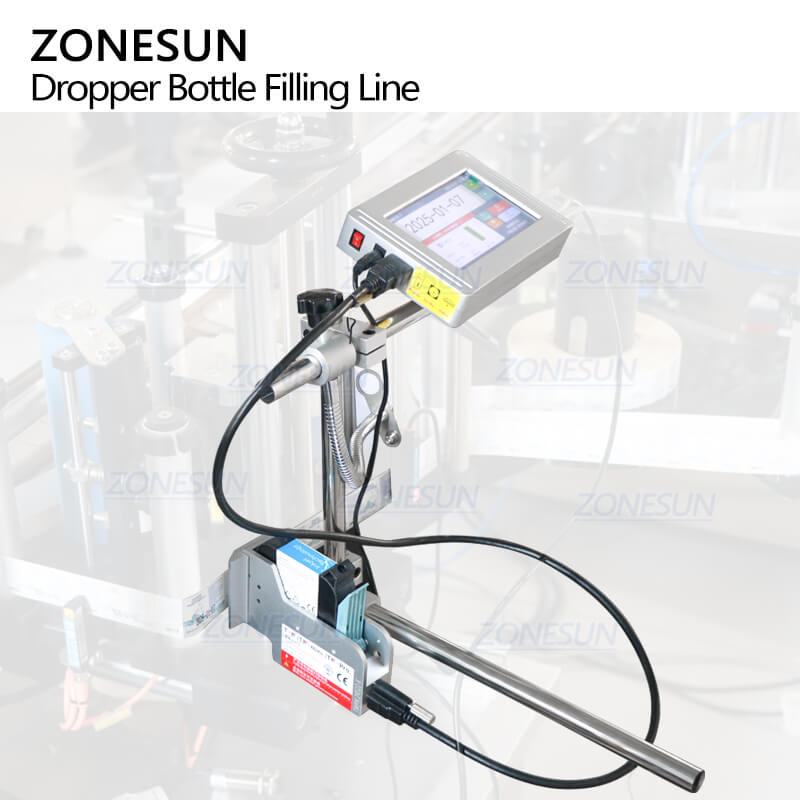

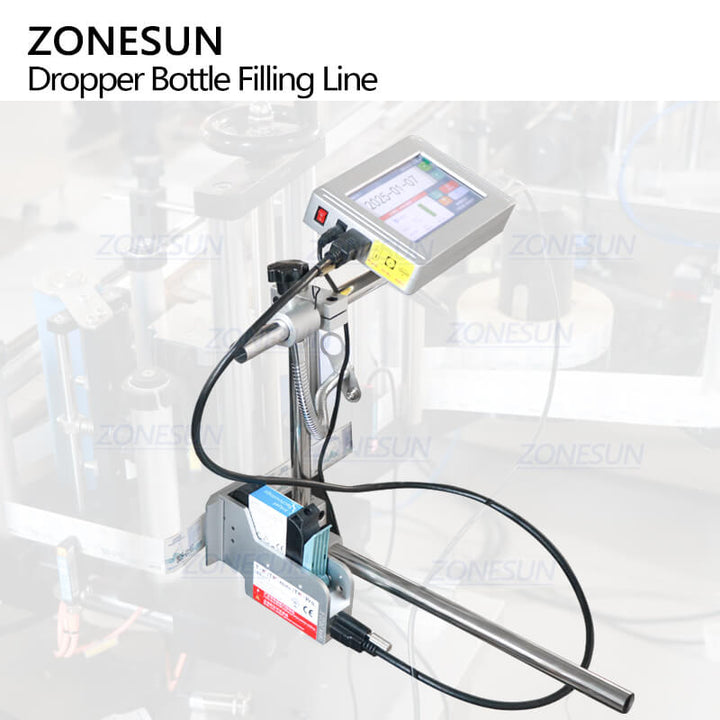

Inkjet Coder

It is suitable for print batch number, production date, QR code on stickers during labeling work.

Bottle Turntable

Size of turntable machine is customizable based on production, saves working labor.