You may also like

Order now! Get at least 2% off here. Don't miss out!

- Home

-

Products

-

Industry

- Oversea Warehouse

- New Arrival

- Promotion

-

Your cart is currently empty.

Earn 0 points on this purchase.

This linear turntable filling and capping machine uses a servo piston pump for filling, it is equipped with double filling heads to ensure packaging efficiency. The vibrating bowl sorter is used to sort caps before capping, and the servo motor control capping work. This machine is suitable for filling and capping thicker liquid like syrup, and is widely used in cosmetics, food seasonings, daily chemical products and other industries.

Parameter

Touch screen interfaces allow for easy customization of controls and settings, making it simple to adjust parameters for different products and production requirements. This flexibility enhances the versatility of the filling and capping machine.

Equipped with pneumatic anti-dripping filling nozzles, these are designed to prevent dripping of product after filling. This is particularly important for liquids with high viscosity or foaming characteristics, as dripping can lead to product waste, messy production environments, and potential contamination of packaging.

Using air nozzle to pass allows for rapid movement of the caps, improves working efficiency. Servo motor control the capping work, this machine has higher capping accuracy.

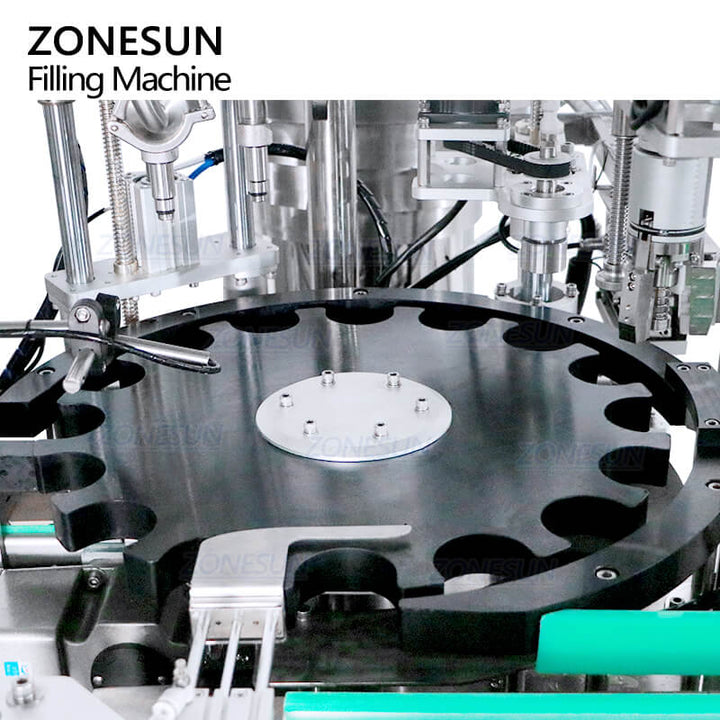

Starwheels provide precise alignment and positioning of containers and caps as they move through the filling and capping process. This ensures that each container is correctly oriented and secured before filling or capping, minimizing the risk of misalignment or errors.

The speed and amplitude of the vibrations in the bowl sorter can be adjusted to control the rate at which caps are fed into the capping machine. This allows operators to match the feed rate of caps with the production speed of the filling and capping machine, optimizing efficiency and preventing overloading or underfeeding.