This monoblock filling capping machine can fill oil into bottles, press stoppers and tighten bottle caps at the same time.Compact machine body saves working space, it is suitable for low viscosity liquid and can work with automatic labeling machine to realize automated production.

Parameter

- Machine model: ZS-AFC33

- Machine voltage: 110/220V 50-60HZ

- Machine power: 1 KW

- Production speed: 10-25 BPM

- Max flow rate: 1.5 L/min

- Recommend filling range: 1-30 ml

- Filling pump: Peristaltic pump

- Suitable bottle size: Customized

- Bottle cap size: Customized

- Air pressure: 0.4-0.6 Mpa

- Package size: About 1760*1180*1550 mm

- Package weight: About 486 kg

Equipped with touch screen control panel, this allow operators to save and recall machine settings for different products or production runs, streamlining changeovers and setup.

By automating the sorting process, vibratory bowl sorting machines can help reduce the need for manual labor, leading to cost savings and improved efficiency in manufacturing operations.

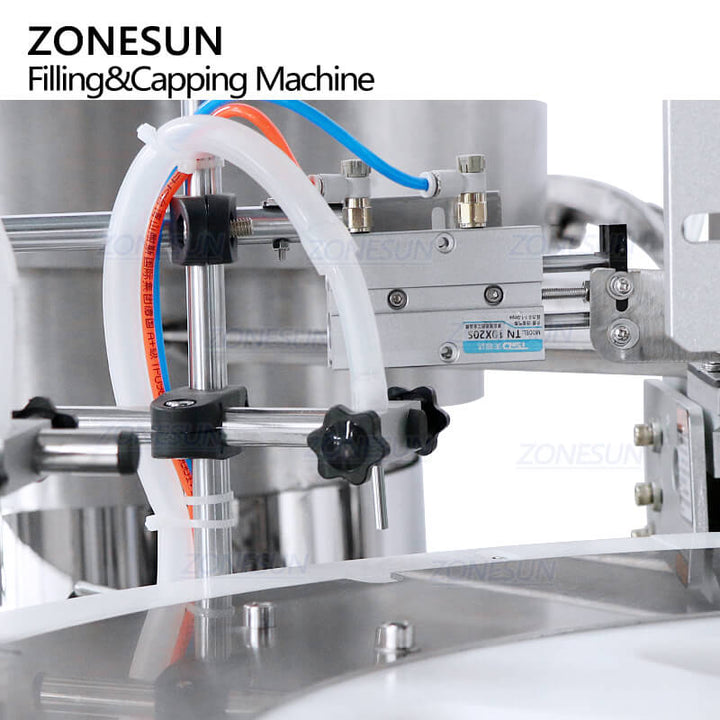

Filling work is controlled by peristaltic pump, because the fluid is contained within the tubing and never comes into contact with the pump mechanism, peristaltic pumps are highly resistant to contamination. This can reduce the risk of cross-contamination between different samples or batches.

Electric eyes use light beams to detect the presence or absence of objects without physical contact.This reduce maintain cost.Electric eyes feature adjustable sensitivity settings, allowing users to fine-tune the sensor's response to different types of objects or varying environmental conditions.

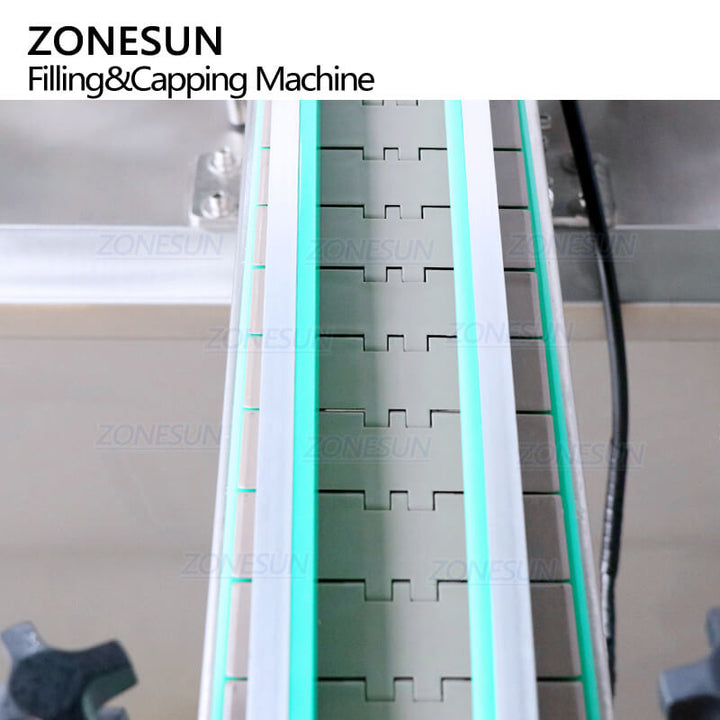

Chain conveyors can be easily integrated with automation systems such as automated labeling machine, increasing efficiency and reducing labor costs.