The monoblock machine controls filling and capping work by cam system, each working station can work at the same time. It has higher working capacity, it can reach 30-40 BPM, suits liquid products in small containers like car perfume, massage oil, machines can be customized for irregular bottles and caps.

Parameter

- Machine model: ZS-AFC28A

- Machine voltage: 110/220V 50-60HZ 2.5KW

- Filling pump: Peristaltic Pump

- Filling range: 4-20 ml (Adjustable)

- Filling error: ±0.1 ml(based on filling range and material)

- Working capacity: 30-40 BPM

- Suitable bottle size: φ25mm*59 mm & φ35 mm*30mm(Customizable)

- Suitable stopper size: φ35mm*30mm(Customizable)

- Suitable cap size: φ35mmX32 mm (Customizable)

- Air pressure: 0.5-0.7 MPa

- Machine size: 2000×1600×1750 mm / 78.4*62.99*68.9 inch

- Machine weight: About 700kg

Control Panel

Touch screen control panels shows parameter setting intuitively, operation language is customizable.

Filling Structure

Quantity of filling nozzles is customizable, peristaltic pump ensures liquid only pass through hose, production is cleaner.

Double Vibratory Bowl Sorter

For arranging stoppers and outer caps in order, it is customizable based on products size.

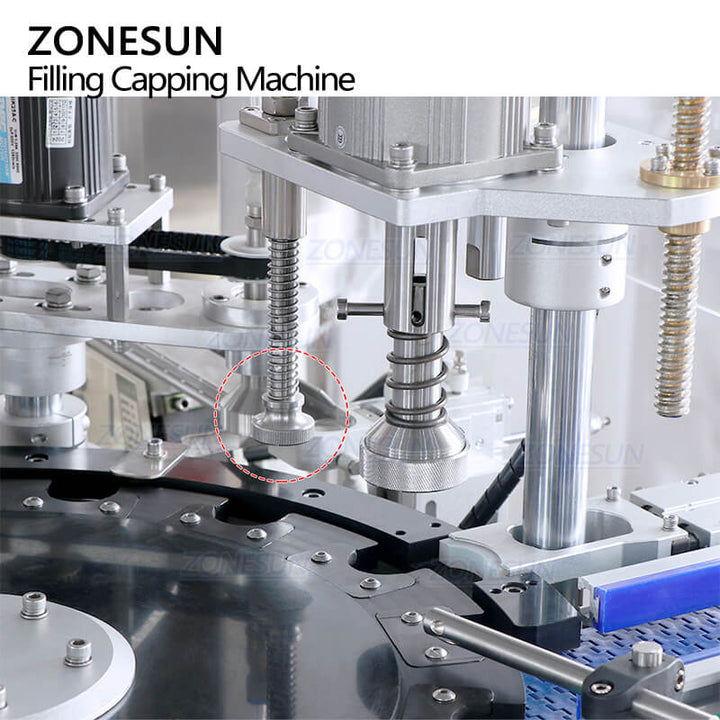

Working Station

Cam system controls packaging work, each working station can work at the same time, it can reach 30-40 BPM.

Cap Positioning Structure

It can position caps before capping work, improves capping accuracy.

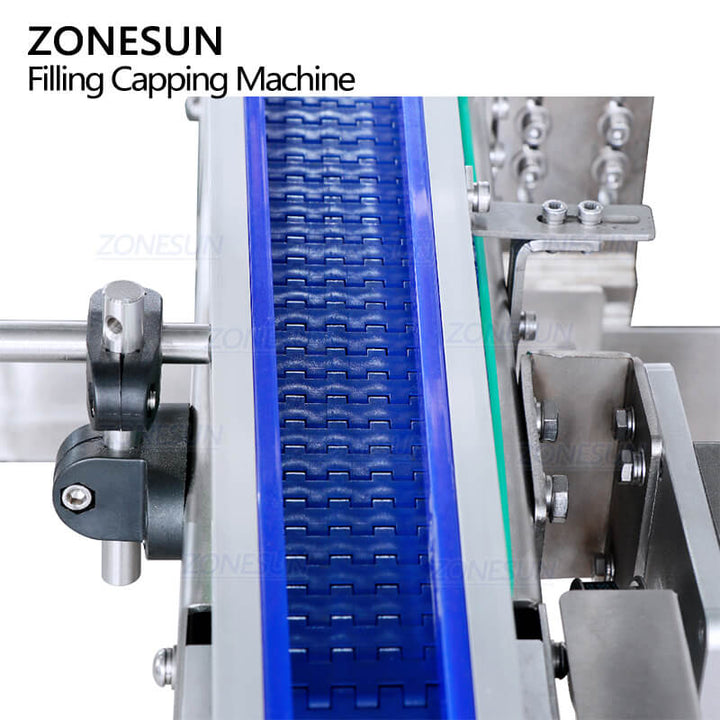

Chain Conveyor

Width and length are customizable based on production need, it ensures smooth working status.