You may also like

Order now! Get at least 2% off here. Don't miss out!

- Home

-

Products

-

Industry

- Oversea Warehouse

- New Arrival

- Promotion

-

Your cart is currently empty.

Earn 0 points on this purchase.

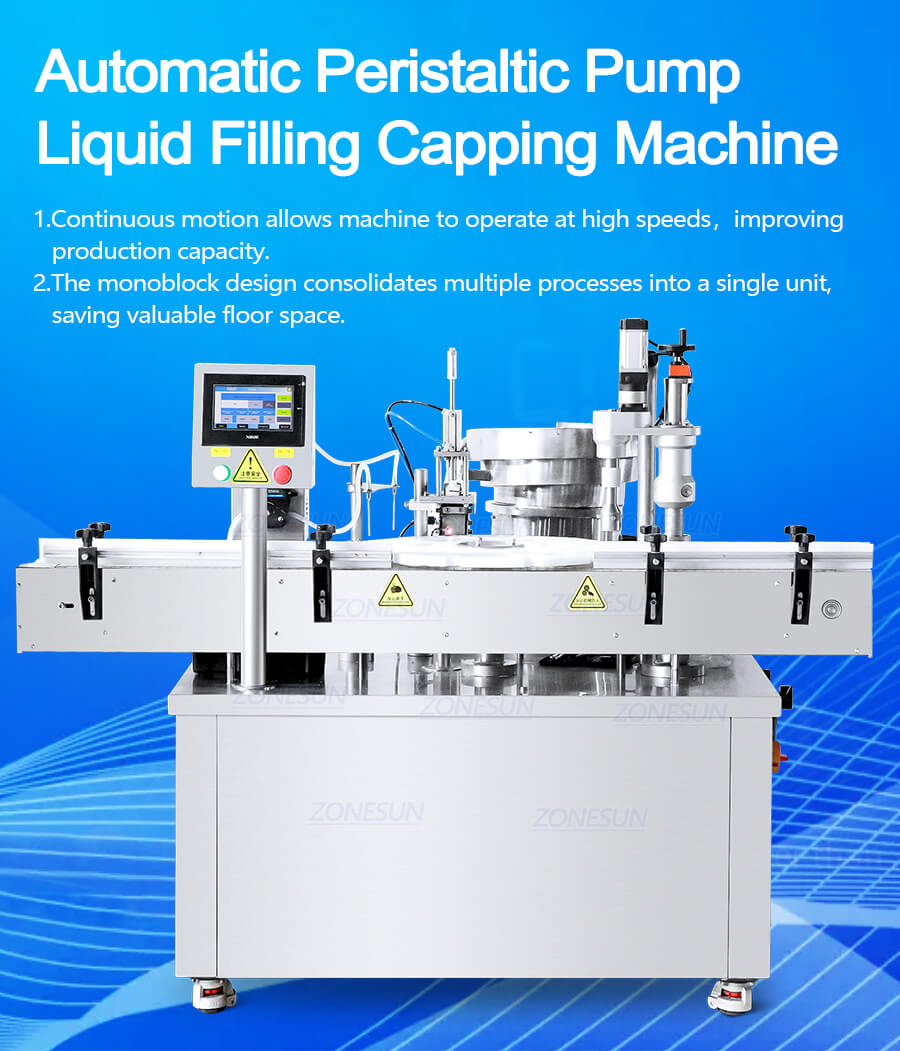

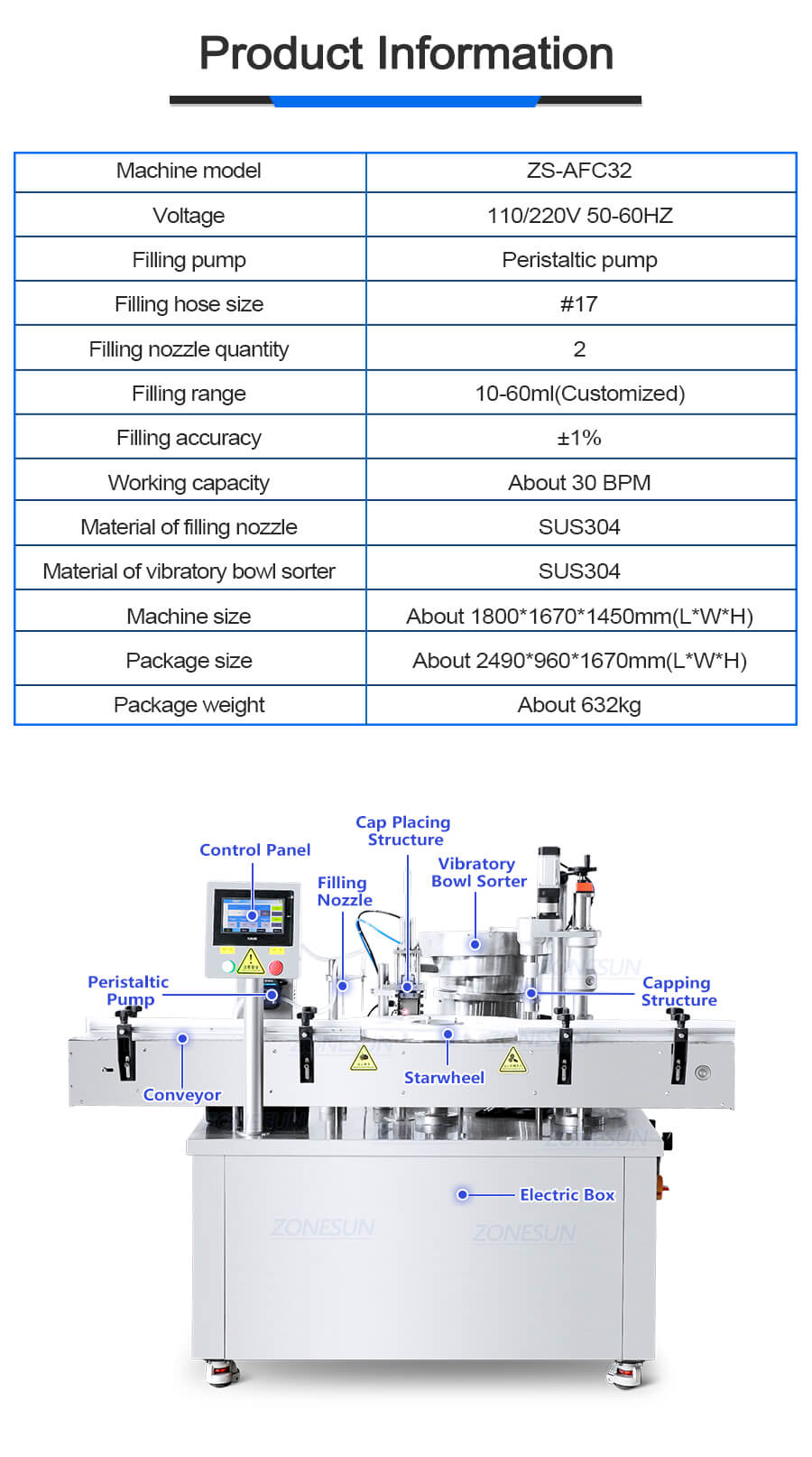

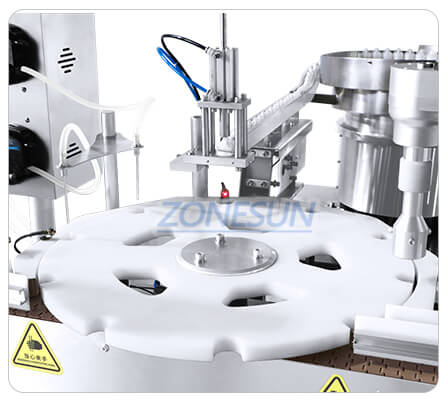

This filling capping machine utilizes cams, which are mechanical devices with specially shaped profiles, to control the motion and positioning of components within the machine.Continuous motion technology allows CAM-position machines to operate at high speeds, resulting in increased throughput and productivity compared to intermittent motion machines.It is suitable for filling essential oil, eyedrops, solvent.

Parameter

This machine features intuitive touchscreen interfaces or control panels, making them easy to operate and monitor. Operators can adjust settings, track production metrics, and troubleshoot issues conveniently from the interface.

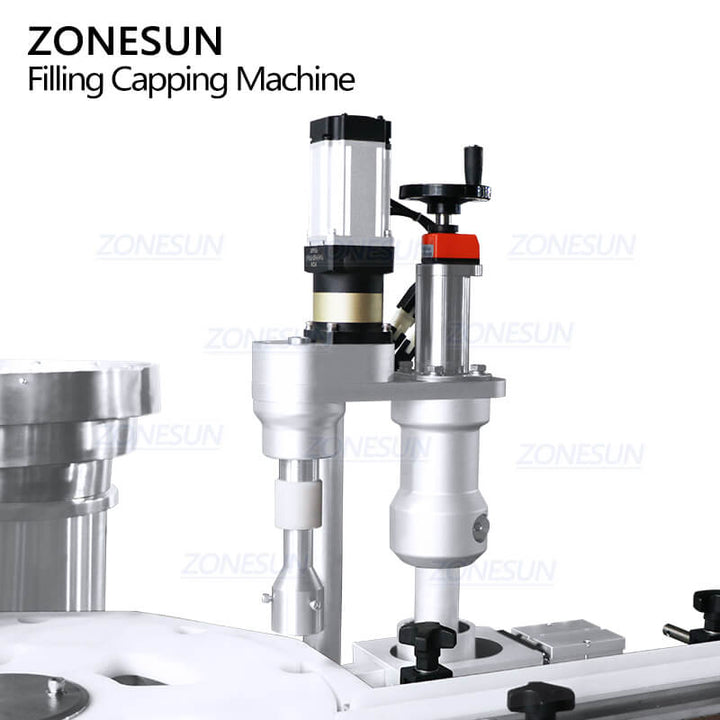

Peristaltic pumps have a unique pumping mechanism where the product is contained within the tubing and never comes into contact with the pump components. This design prevents cross-contamination between different products and ensures product purity and integrity.

There is an electric for each working station has, which can detect passing bottles and control the machine to start automated work.If no bottles pass by, the cap placing structure will not work, this can prevent from wasting caps.

There is an electric for each working station has, which can detect passing bottles and control the machine to start automated work.If no bottles pass by, the cap placing structure will not work, this can prevent from wasting caps.

Servo motors offer precise control over capping torque, allowing for accurate tightening of caps to the desired specifications. This minimizes the risk of over-tightened or under-tightened caps.