The liquid filling machine is used to dispense and fill liquid into containers such as bottles, jars, cans, pouches. They are usually used for packaging drinks, liquor, skin toner, lotion, detergent, essential oil, cleaning agent, chemical corrosive liquid, flammable liquid. These machines are widely used in various industries, including food and beverage, pharmaceuticals, cosmetics, chemicals, and household products.

Completed Packaging Solution

More for Wating Update...

Filling Machine For Other Material

What types of liquid filling machines are available?

From the principle of filling, liquid filling machines can be roughly divided into:

- Gravity Filling Machines: Utilize gravity to fill containers with liquid, suitable for low-viscosity liquids.

- Piston Filling Machines: Fill using the reciprocating motion of a piston, suitable for medium to high viscosity liquids and pastes.

- Pump Filling Machines: Use various types of pumps (magnetic pump, gear pump, peristaltic pump, etc.) for filling, suitable for liquids of all viscosities.

- Overflow Filling Machines: Ensure that containers are filled to a consistent level, suitable for transparent containers.

From the level of automation, liquid filling machines can be divided into:

- Manual Liquid Filling Machines

- Semi-Automatic Liquid Filling Machines

- Fully Automatic Liquid Filling Machines

What are the key considerations when choosing a liquid filling machine?

- Viscosity of the Product: Determines the type of filling machine and the filling speed.

- Production Volume: High-volume production lines may require fully automated systems, while lower volumes might use semi-automatic or manual machines.

- Container Type and Size: Machines need to accommodate various container shapes and sizes.

- Accuracy Requirements: Some applications require precise volume control, which affects the choice of filling technology.

- Product Feature:

- For products requiring sanitary conditions, such as food and pharmaceuticals, material compliance (e.g., stainless steel) is critical.

- For corrosive chemical liquid, The material of the machine components that come into contact with the material or the components of the entire machine will be very important.( we recommend PP material)

- For foamy liquid, you will need to consider the diving filling nozzles for your filling machine

What industries commonly use liquid filling machines?

- Food and Beverage: For products like juices, sauces, and dairy.

- Pharmaceuticals: For medicines, syrups, and other health products.

- Cosmetics: For creams, lotions, essential oils,and cosmetic serum.

- Chemical: For household cleaners, agrochemicals, and industrial liquids.

- Petrochemical: For lubricants and oils.

What are some key common features and benefits of liquid filling machines?

- Anti-dripping Filling Nozzles: It can be customized to handle different viscosities and to prevent dripping or splashing.

- Diving Filling Nozzles: Designed for preventing foamy liquid from splashing out during filling work

- Food Grade Stainless Steel Construction: Meet sanitary standards, crucial for food and pharmaceutical applications.Good for jam, hot saue, honey, cough syrup etc.Enhances durability and eases cleaning, maintaining hygiene standards.

- Adjustable Settings: Allows for control over filling speed and volume(servo system filling machine), catering to different container sizes and production needs

- Custom Hopper: A reservoir that holds the paste product before dispensing filling material. Heating and stirring mechanism can be customized for keeping the paste uniformly mixed.

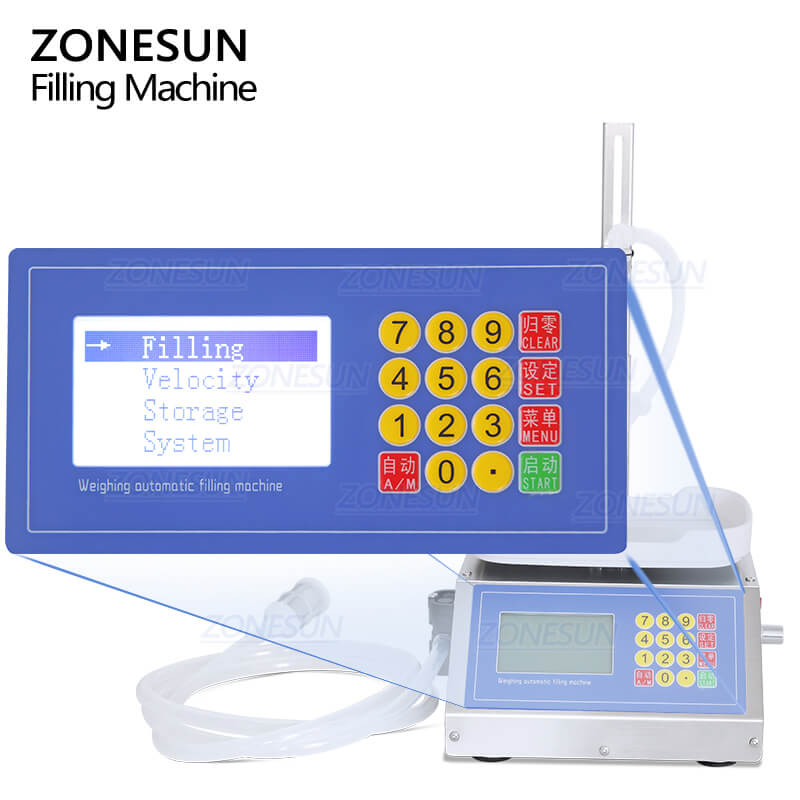

- PLC Control Systems: Offer user-friendly interfaces for setting and monitoring machine parameters.Different kindso f operation language can be customized

Do you provide maintenance and support for paste filling machines?

Yes, we provide maintenance services, training, and support to ensure the optimal performance of filling machines. like

- One-year Warranty: Free replacement of parts within the warranty period, except for easily damaged parts. Out of the warranty period, you can still contact us for any questions about the machine (machine maintenance, parts purchase)

- After-sales Service: Offer user manual, install &debugging video, one-to-one video chat, oversea after-sales service( in some area)

- Oversea Warehouse: Some machines can be shipped from overseas warehouses to reduce delivery time and cost.

- Custom Packaging Solution: Offer one-stop packaging solution through detailed packaging production need.