Introduction

This automatic labeling machine is with two labeling heads,one for flat surface,one for round bottles.It is normally used for labeling bottle caps and bottles at the same time.This machine is widely used in food, daily chemicals,cosmetics industries.

Parameter

- Model:ZS-TB822D Labeling Machine

- Power Supply:AC110V/220V 50Hz/60Hz 5000W

- Labeling Capacity(bottles/min):25-45 bottles/min(depends on bottle size)

- Labeling Accuracy(mm):±1.0mm

- Suitable Bottle Diameter:Φ25-100mm

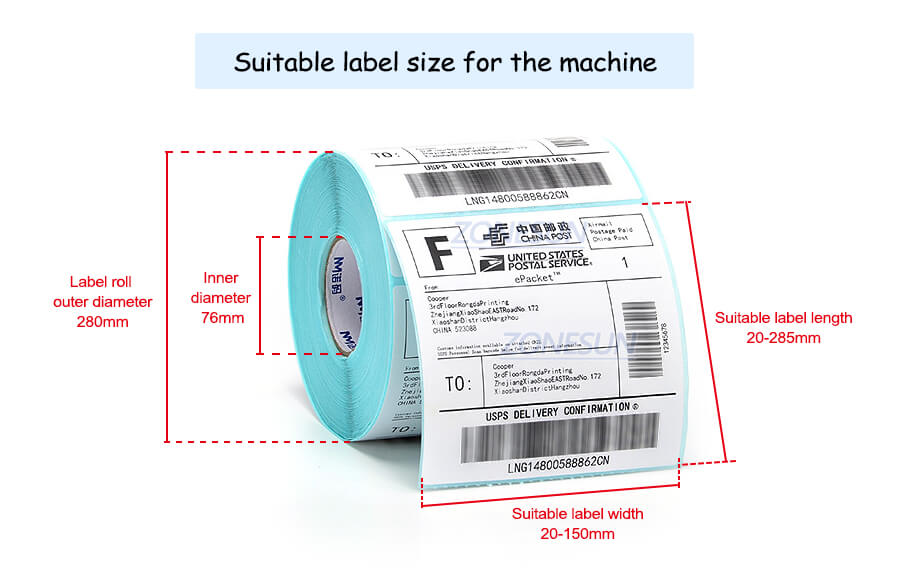

- Label Size(mm):(L)20mm-285mm* (H)20-150mm

- Roll inside Diameter(mm):Φ76mm

- Roll outside Diameter(mm):Φ280mm

- Conveyor Size:100*2380mm(W)

- Machine Size:About 2550*1080*1590mm

- Package Size:About 2550*1140*1685mm

- Net Weight/Gross Weight:About 378kg/523kg

Design with touch screen control panel,it is more convenient to adjust machine parameter.We can customize the control panel in different kinds of languages,if you need this please contact us.

The bottle separating wheel is used to separate bottles during working,makes the production can be in order,reduce production error and improve working efficiency.

With two kinds of labeling head,this machine can be used to labeling sticker on flat surface and wrapping around bottles.The electric eyes can be used to detecting objects,improves labeling accuracy.

The chain conveyor belt is with larger loading capacity,it can help to transport bottles.The guard railing can be adjusted according to bottles diameter,makes sure the bottle can be conveyed smoothly.

The machine is designed with collecting plate to collect finished products,this prevent that bottles fall from conveyor belt and give more time to operator to collect finished products.