You may also like

Order now! Get at least 2% off here. Don't miss out!

- Home

-

Products

-

Industry

- Oversea Warehouse

- New Arrival

- Promotion

-

Your cart is currently empty.

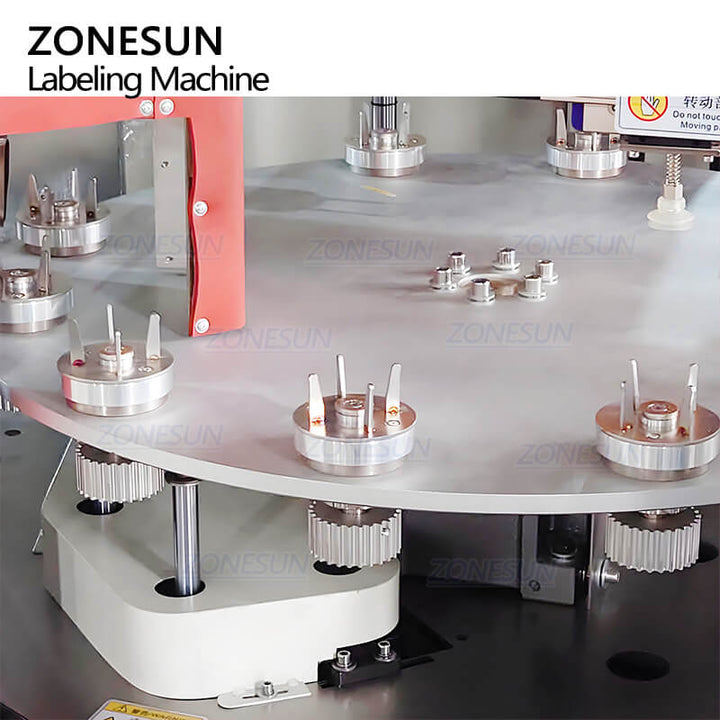

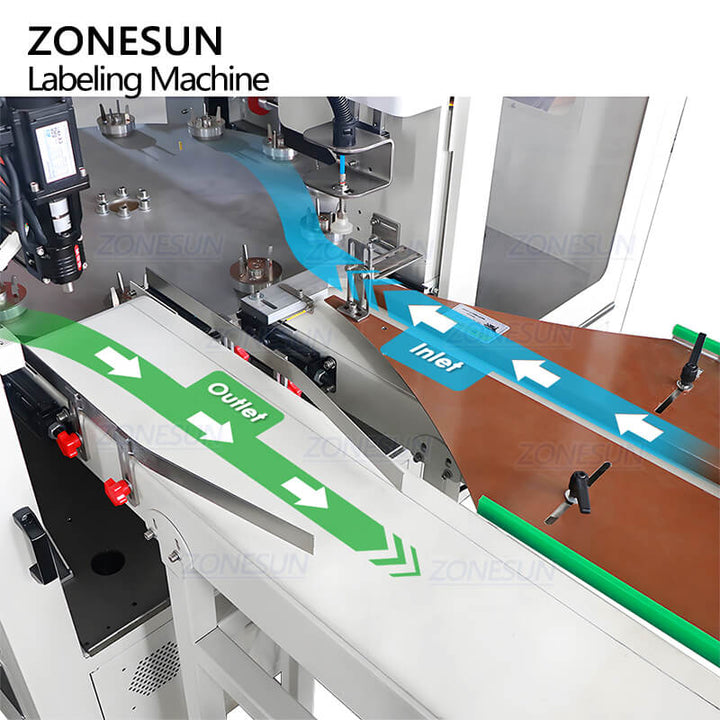

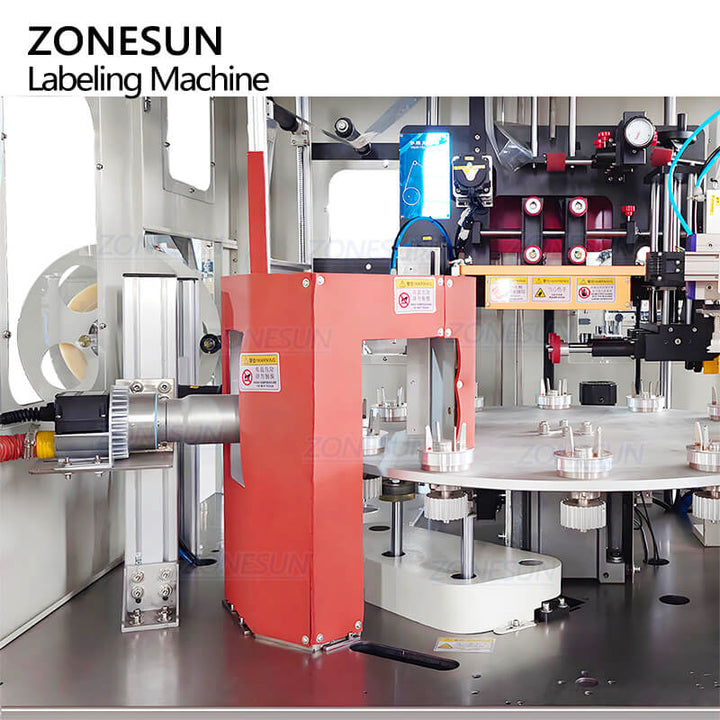

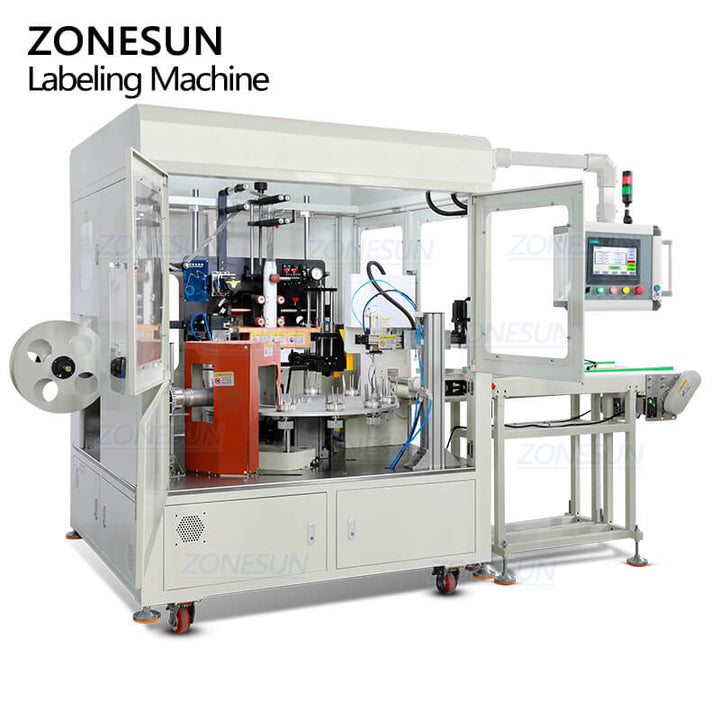

The Automatic Rotary Shrink Sleeve Labeling Machine features an adjustable constant temperature system for precise heat control and a compact turntable design for space efficiency. With one-click intelligent operation and an automatic fault alarm, it ensures user-friendly and reliable performance. The interchangeable mold allows for flexible adaptation to different bottle sizes, while the servo motor control enhances transmission efficiency, making it an ideal solution for high-precision labeling in various industries.

Parameter