Designed for efficient and precise sauce packaging, featuring a piston pump filling system that ensures accurate dosing for tomato paste, chili sauce, and other viscous condiments. With fully automated operation, it seamlessly integrates filling, tube sealing, and date printing, reducing labor costs and enhancing productivity. Additionally, the trimming structure ensures a neat and professional seal for every tube. This machine can be customized to meet your specific production requirements, making it reliable solution for your packaging needs.

Parameter

- Machine Model: ZS-FS008U

- Voltage: 220V/110V 50-60 Hz

- Power: 4 kW

- Production Speed: About 15 PCS/Min (depending on tube size and filling materials)

- Filling Pump: Piston Pump

- Filling Range: 6-60 ml/ 10-120 ml/ 25-250 ml(Can be customized)

- Applicable Tube Size: Can be customized

- Filling Error: ±1%

- Sealing Method: Ultrasonic Sealing

- Ultrasonic Frequency: 20 KHz

- Suitable Tubes: Aluminum tubes and aluminum-plastic tubes

- Air Pressure: 0.4-1.6 MPa

- Packaging Size: 1350*1060*1590 MM

- Packaging Weigh: 375 KG

Designed with PLC panel, it is convenient to set and adjust working parameters like sealing time. The language of panel can be customized as your need.

Equipped with piston pump, this machine can fill thick sauce accurately, which suits for filling tomato paste, fruit jam. The filling range and quantity of nozzles can be customize as your need.

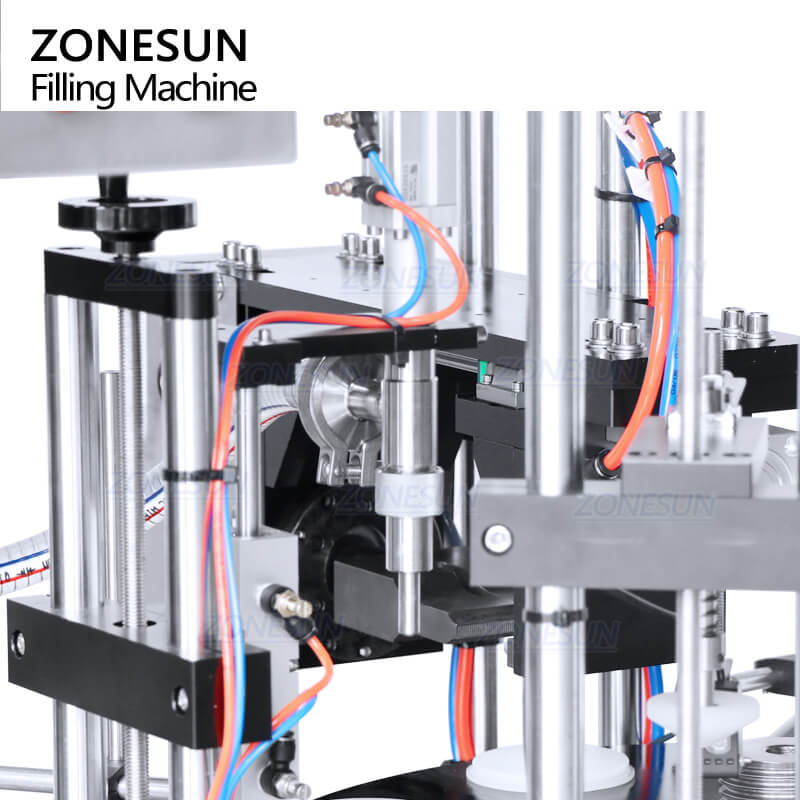

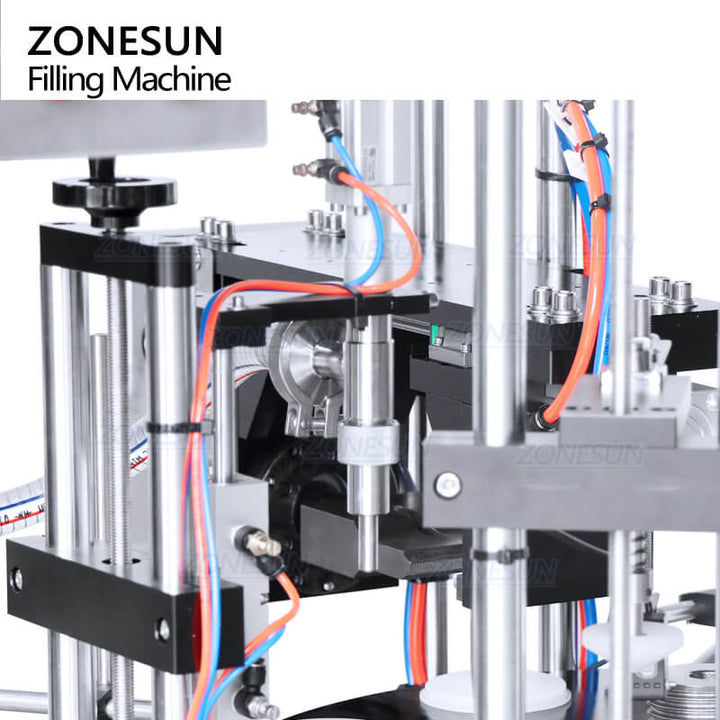

Adopting the method of ultrasonic sealing, this machine can seal sauce tubes firmly. It can be equipped with letter molds, which can print production date automatically.

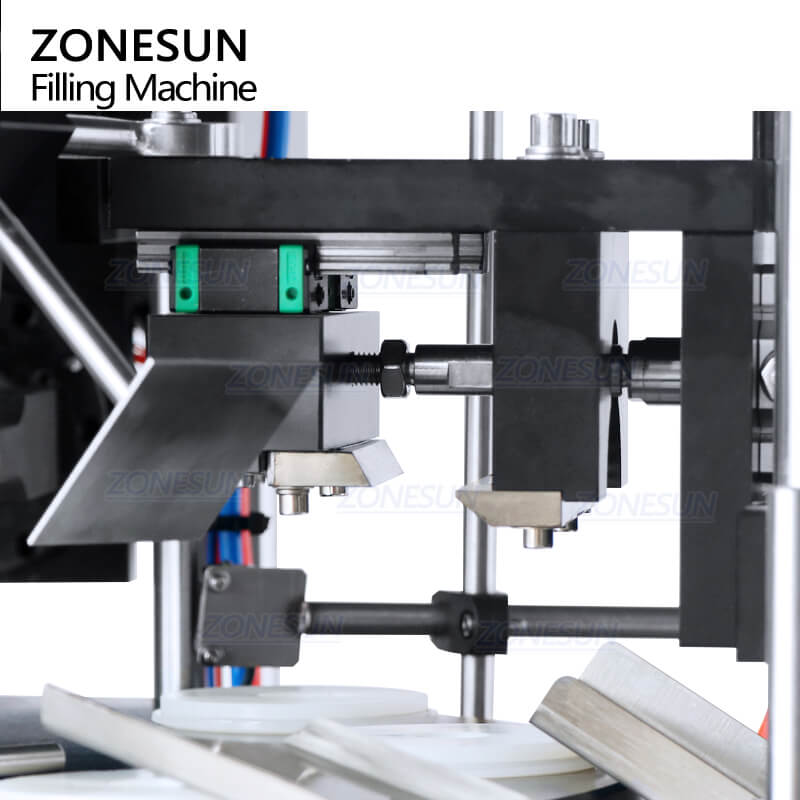

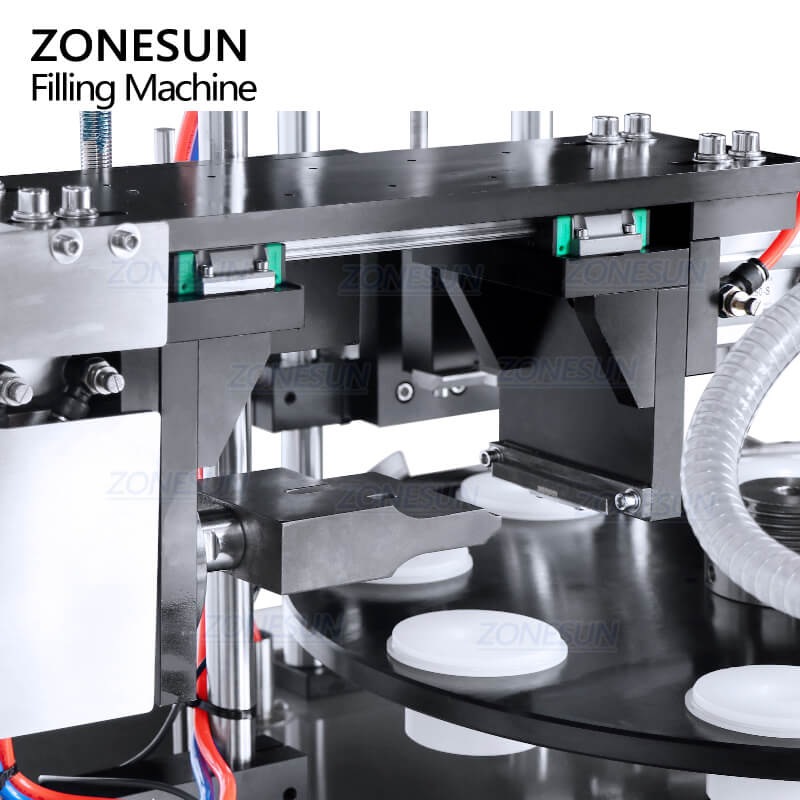

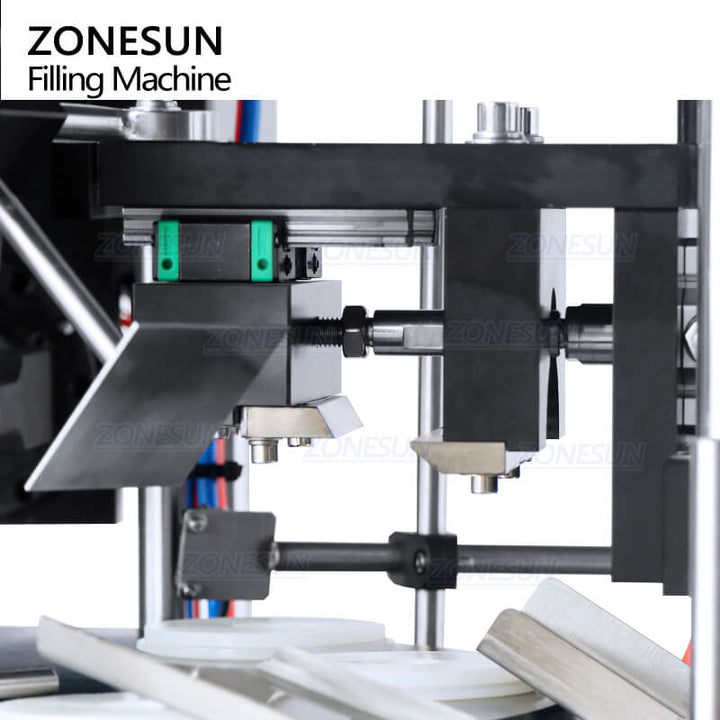

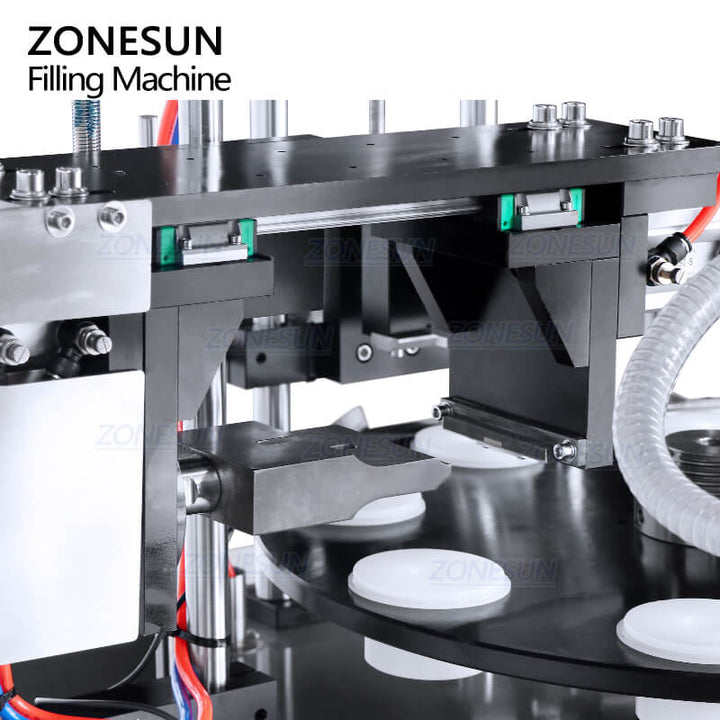

This structure is designed for trimming tubes after sealing, ensuring good production quality. It can be customized according to tube size.

The rotary plate is designed for fixing and transporting sauce tubes during production, helping to improve efficiency. Fixing molds can be customized to suit for your products.