This machine is ideal for capping applications in the seasoning, food, daily chemical, and cosmetics industries. It features fully automated cap feeding, bottle clamping, conveying, and capping functions, improving efficiency and consistency. Designed to accommodate bottles of various shapes, heights, and cap sizes, the machine offers strong versatility. The servo-driven system allows precise adjustment of capping torque, while the pneumatic cap-transfer mechanism ensures stable, accurate, and reliable capping performance.

Parameter

- Machine model: ZS-SVXG01

- Machine voltage: 110/220V 50-60HZ 1.5 KW

- Suitable bottle size: φ=20-150 mm H=20-220 mm

- Suitable cap size: Customizable

- Working capacity: 2100-2300 BPH

- Conveyor size: 2000*114 mm(L*W) Working Height=850 mm

- Machine casing material: SUS304

- Air consumption: 0.4-0.6 MPa

- Machine size: About 3000*900*1550 mm

- Machine weight: About 260 kg

Control Panel

Touch screen control panel makes parameter setting more intuitively, customizable operating language.

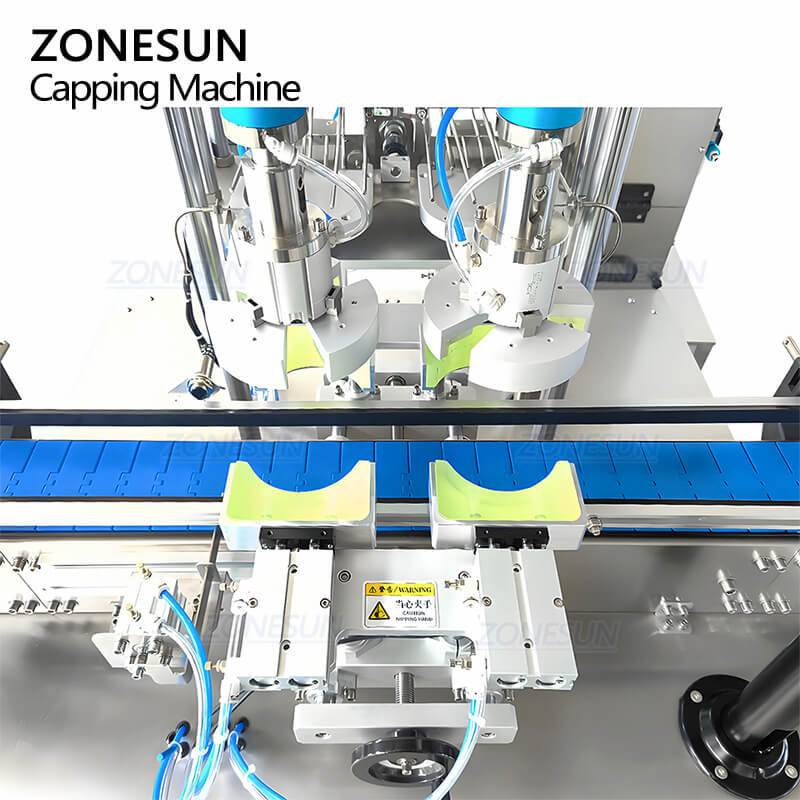

Cap Passing & Capping Structure

Using pneumatic claw for passing caps and capping bottles, it has high working accuracy.

Bottle Clamping Structure

These can fix bottles during capping work to improve capping accuracy.

Cap Elevator

Cap elevator can supply bottle caps in time, it saves working labor and improve working efficiency.