Fully automated granule solution designed for precise weighing, filling, and sealing of granular materials such as nuts, candies. The machine integrates pouch feeding, opening, filling, and sealing functions into a compact design, enhancing efficiency while saving space. This machine is ideal for industries such as food and chemicals, providing a reliable and efficient packaging solution.

Parameter

- Machine Model: ZS-AFS04

- Power Supply: 220V/110V 50-60Hz 920W

- Working Speed: About 22-30 bags/min (depending on bag size and filling materials)

- Weighing Range: 0.1-99.9 g

- Weighing Accuracy: ±0.1 g

- Pouch Size: 50-180 mm(Width)*70-260 mm(Length)

- Hopper Capacity: 30 kg

- Air Pressure: 0.6-0.8 MPa, 0.83 m³/min

- Package Size: About 1090*750*2040 mm(Packing Machine) About 940*500*1270 mm(Dust Collector)

- Package Weight: About 233+72 kg

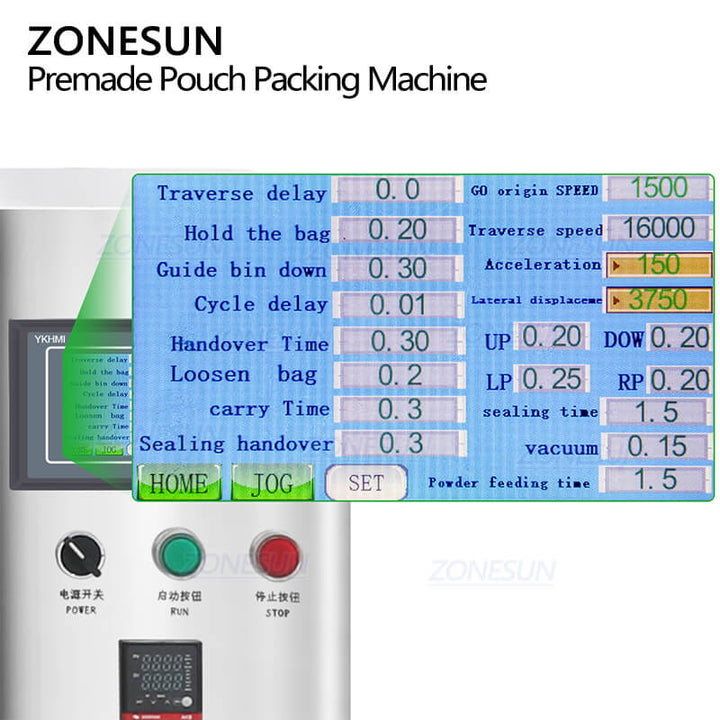

Control Panel

Touchscreen panel makes it easier to adjust working parameters. Multiple languages can be customized.

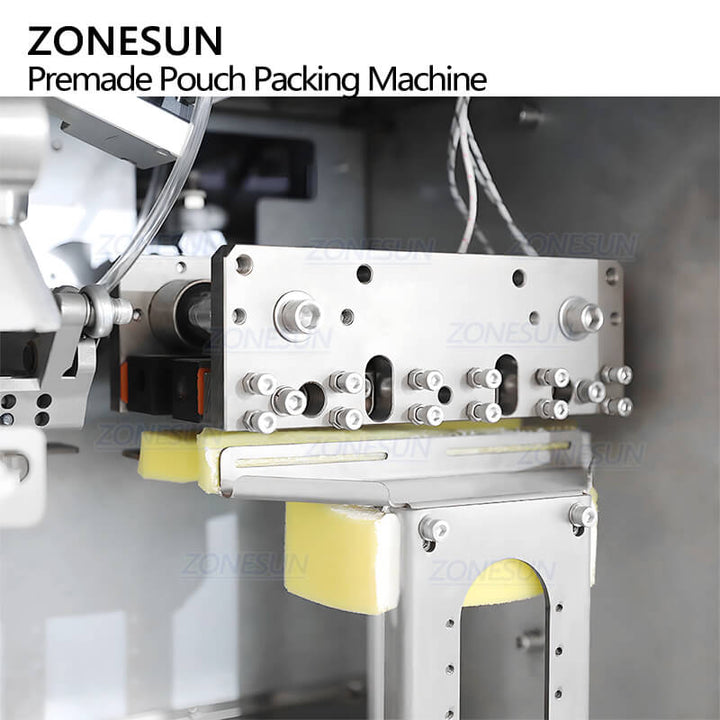

Compact Design

Pouch feeding, opening, filling and sealing are combined at one machine, saving working space.

3 Weighing Scales

The machine adopts the way of weighing and filling, which can pack granules like peanuts. Filling weight can be set on panel as needed.

Vacuum Sealing Structure

The sealing temperature can be adjusted to suit different packaging materials. It has pouch vacuuming function.

Dust Collector

It can remove the dust caused by materials, ensuring production cleanliness.