Labeling machine (label applicator)can dispense or apply labels to bottles,boxes or packages. They can range from single side, double sides, wrap-around labeling machine, allow for manual , semi-automatic or complete automated production of the print and apply process.

Are There Multiple Types Of labeling Machine?

Yes, labeling machines come in various types, each suited to different applications based on the product, label type, and production needs. Here are some common types:

Automatic vs. Semi-Automatic Labeling Machines

Automatic Labeling Machines: These are fully automated systems that can apply labels with high precision and speed, ideal for large-scale production.

Semi-Automatic Labeling Machines: This machine requires the operator to place the container, then press a button or activate a foot pedal to start labeling. These machines require some manual input, often suited for small or medium production scales or operations with varied labeling needs.

Manual Labeling Machine: In this setup, the operator has to place the container and manually apply the label by turning a crank or aligning it by hand.This suits very small scale production.

Wrap-Around Labeling Machines

These apply labels around cylindrical containers, like bottles and jars, this often requires the beggining of the label and the end of the label can nearly connected. The three roller label applicator can meet this high labeling accuracy.

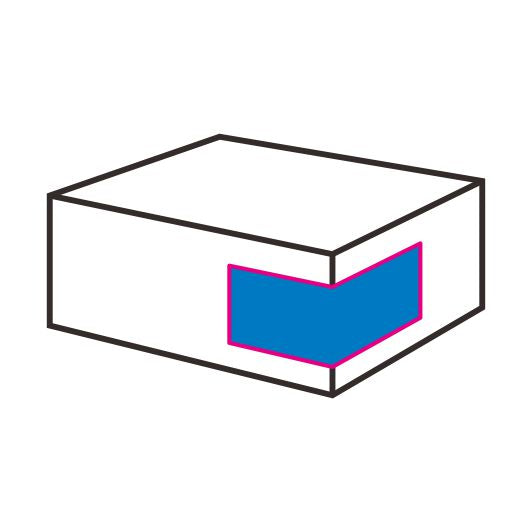

Front and Back Labeling Machines

Used for containers that need two labels—one on the front and one on the back—such as laundry detergent bottles, engine oil jerry cans, this type is often found in personal care, food, and cleaning products.

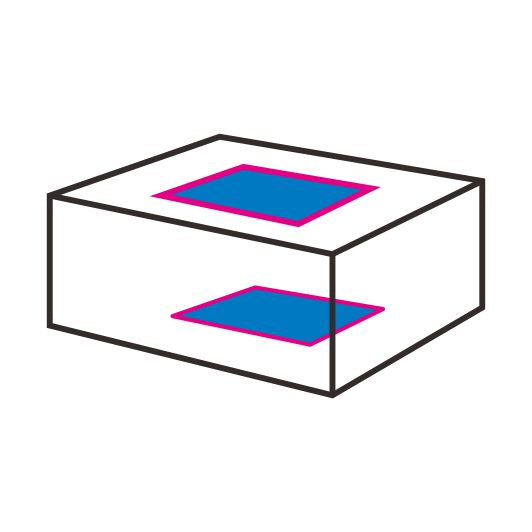

Top and Bottom Labeling Machines

These label the top and/or bottom surfaces of containers, ideal for flat products like hanging tag, pouches, trays, lids, and cartons. They’re frequently used in food packaging.

Tamper Evident Labeling Machines

Tamper-evident label applicator is a specialized labeling machine designed to apply tamper-evident labels, which are labels that reveal any signs of tampering when removed or altered. These labels are commonly used in industries such as pharmaceuticals, food and beverage, cosmetics, and electronics. The applicator ensures that these labels are applied consistently and securely over closures, seams, or vulnerable areas of a package.

Shrink Sleeve Labeling Machines

These apply heat-shrinkable labels that contour to the shape of the container, giving 360-degree coverage and a tamper-evident seal, which is often used for beverages, pharmaceuticals, and cosmetics.

Each type of labeling machine has features and advantages that cater to specific product shapes, materials, and production speeds.

What Information Will Need To Be Provided When Customizing a Label Applicator?

When customizing a labeling machine, providing detailed information about your product, production requirements, and operational preferences ensures the machine will meet your needs effectively. Here’s what to consider sharing:

Product Specifications

Labeling Object Type and Shape: Describe whether containers are cylindrical, rectangular, or uniquely shaped.

Labeling Object Dimensions: Include height, width, diameter, and any unique structural elements .

Label Specifications

Label Size and Shape: Provide the dimensions and shape (rectangle, square, oval, etc.) of the labels.

Label Type: Indicate if it’s pressure-sensitive, shrink-sleeve, or wrap-around, for example.

Label Positioning: Specify whether labels need to be placed on the front, back, top, bottom, or multiple sides.

Production Requirements

Production Speed: State the number of containers to label per hour or per minute.

Automation Level: Decide between fully automated or semi-automated, depending on production volume and budget.

Accuracy Requirements: Share any specific placement precision requirements.

Integration with Existing Equipment

Production Line Layout: Share layout diagrams and indicate where the labeling machine will fit into the production line.

Machine Compatibility: List any existing machinery the labeling machine must work with, such as conveyors, filling machines, or packaging machines.

Additional Features

Label Sensors: If you need specific sensors for clear labels or specific surfaces, mention this.

Printing Requirements: Indicate if you need an integrated printer for lot numbers, expiration dates, or batch codes.

User Interface and Controls: Share preferences for touchscreens, language options, or any remote monitoring capabilities.

Providing these details will allow your machine manufacturer to design a labeling machine tailored to your operational requirements.